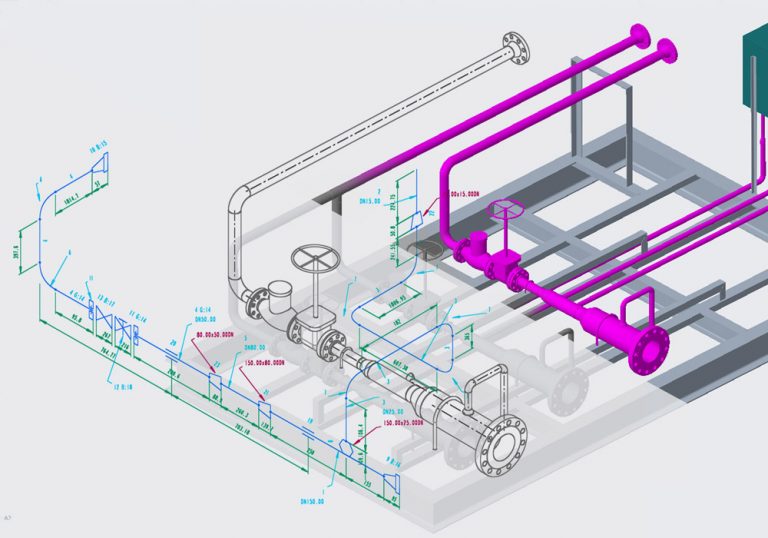

Automatic Piping Isometrics for Fabrication and Installation

for M4 PLANT

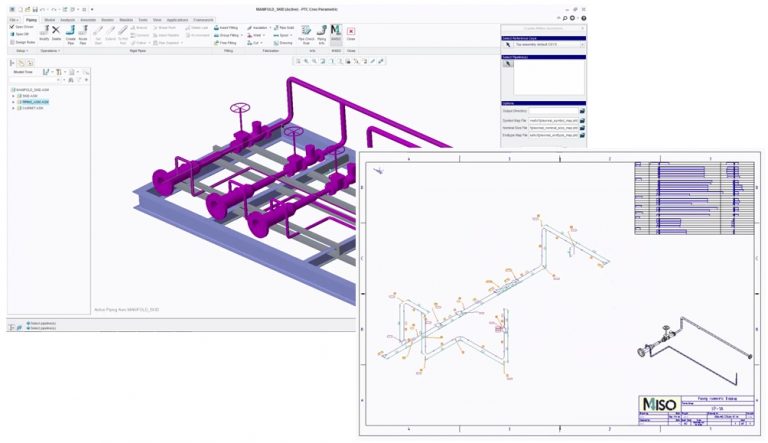

for Creo Piping

M4 ISO is available as an add-on module for Creo Piping and automatically generates piping isometrics from Creo piping models.

Piping Isometric Drawings from 3D Pipework Designs

Advantages for your company

M4 ISO works completely automatically enabling you to generate piping isometrics in a few seconds without manual effort.

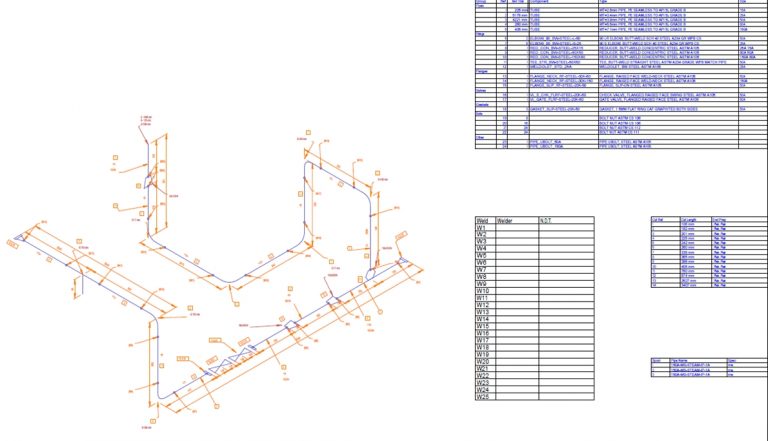

All isometrics and parts lists are generated ready for production and styled to suit your processes. Bend data can also be output for NC pipe bending machines.

Support for Metric and Imperial units and all common dimensioning standards. Drawing styles and templates are also customisable.

Our team supports you as a partner and offers you a comprehensive service with a hotline for your daily questions.

M4 ISO Functionality

Unscaled

Dimensioning

Labelling

3D view

Bending tables

Breaks

Welding lists

Pipe Positions

Elevations and falls

Customisable symbols

Style templates

Genaue

Stücklisten

More functions

- Automated piping isometrics

- Configurable detailed dimensions

- Unscaled & unambiguous

- Customisable templates & styles

- Detailed parts lists

- Parts lists as tables & files

- Bend tables and welding lists

- Extendable with design notes

The fastest way to create piping isometrics

Pipework designs documented in line with production requirements

Get started with M4 ISO now

More security through comprehensive consulting and software testing

Apply for your trial license or contact our consultants. With our tutorials and online support you can easily try out the software. Our staff will advise and help you select the best package for your requirements.

Start quickly with on-site workshops and training courses

In addition to standard training courses, we also offer on-site workshops, which enable you to receive tailored training while working on your first project. This guarantees you the fastest possible start into the productive use of the software.

Continuously productive and always up-to-date

Our software maintenance includes extensive support including telephone support, all software updates and access to our customer portal. This enables us to effectively support you throughout your day.

Start your free trial now or contact us for advice

If you have further questions about the software, need an offer or would like to learn more about our additional services, please contact us. Our consultants will be happy to answer any questions you may have. +44 1223 850 942 or E-Mail

FAQ: Your frequently asked questions and our answers

- PCF = Piping Component File.

- A PCF file is generated by piping design systems from 3D pipework models.

- The PCF file fully describes the 3D pipework and is a standard file format.

- M4 ISO generates a fully dimensioned piping isometric drawing from the PCF file, together with a parts list.

Simply contact our consultants. Use the contact form or simply call us: +44 1223 850 942