Create piping isometrics directly in Creo Piping

Piping isometrics (ISOs): The most important design drawing used in pipework construction

Piping ISOs automatically generated in seconds

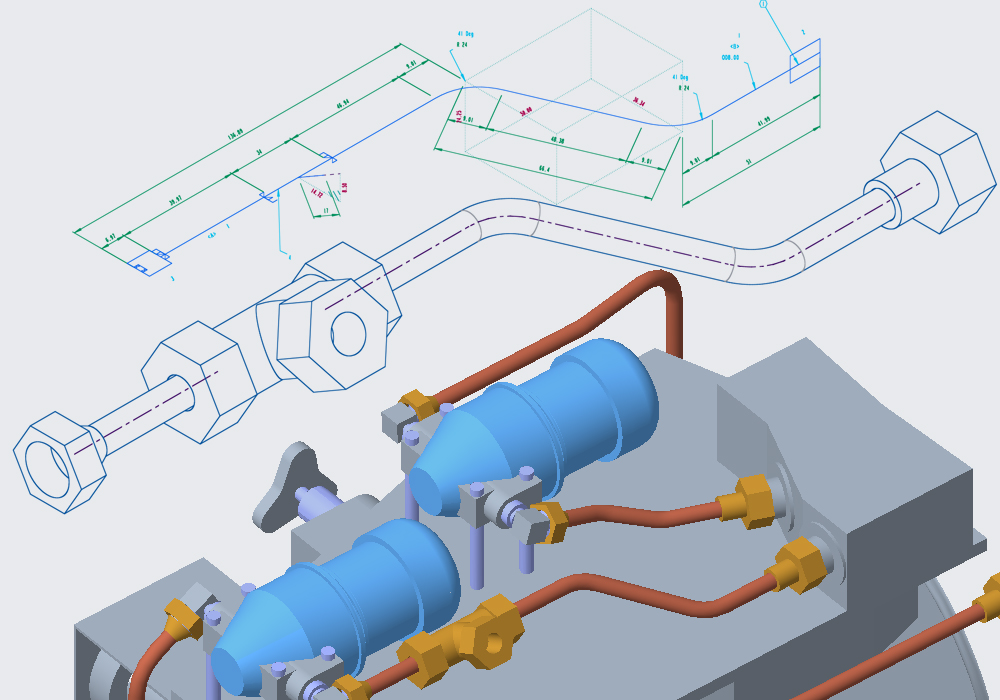

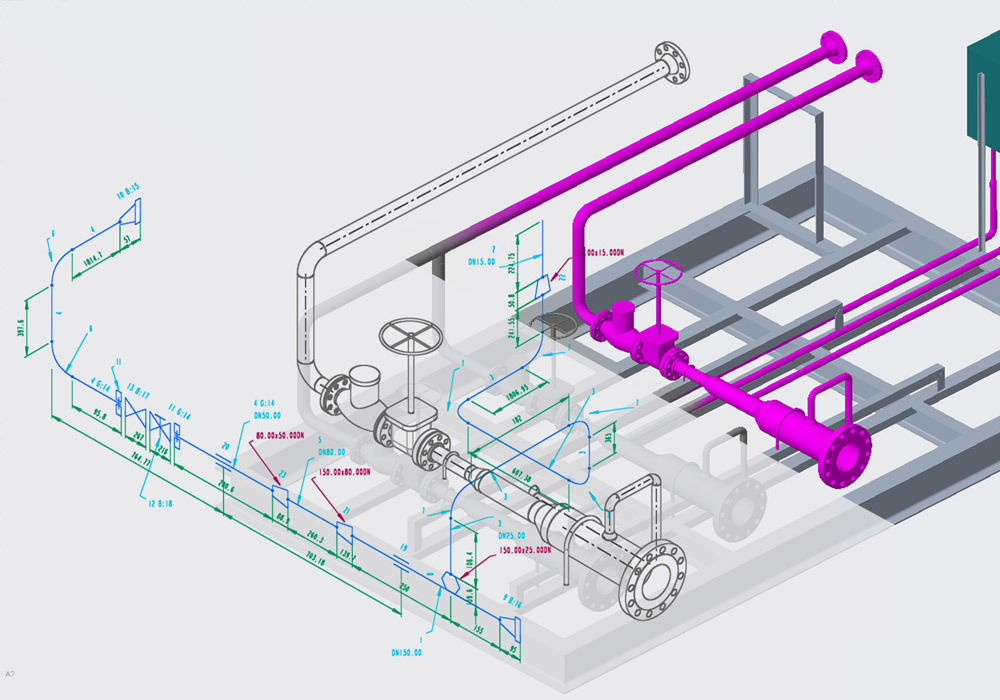

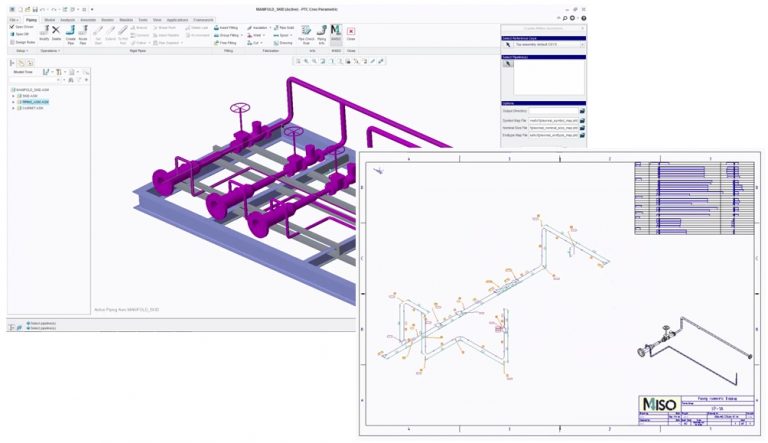

M4 ISO uses 3D pipework data from PTC Creo Piping to automatically create unscaled piping ISOs together with parts lists and other associated documents. The documents are produced in seconds, ready for production use, and styled to suit company drawing standards. The automatic production of piping ISOs offers tremendous advantages over manually drawn 2D or isometric drawings, which in comparison are time-consuming to produce, highly prone to human error, and therefore inferior and much more expensive. With M4 ISO, project costs are always under control, even if the design undergoes numerous revisions before manufacture.

Advantages for your company

M4 ISO is fully integrated with Creo Piping. It allows you to automatically generate your isometrics directly in Creo.

M4 ISO works completely automatically enabling you to generate piping isometrics in a few seconds without manual effort.

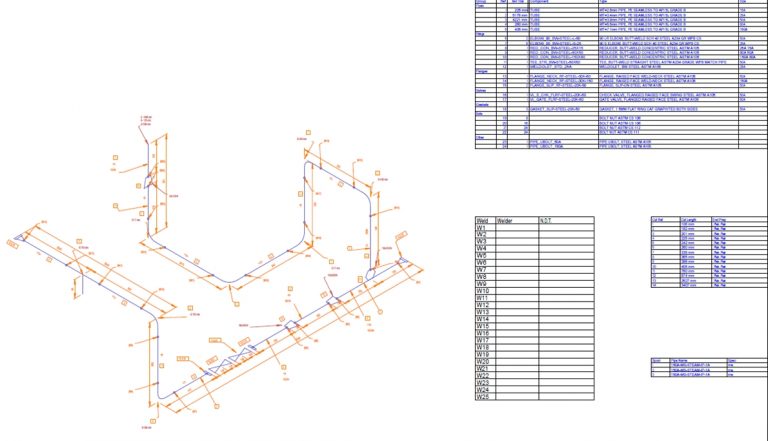

All isometrics and parts lists are generated ready for production and styled to suit your processes. Bend data can also be output for NC pipe bending machines.

Support for Metric and Imperial units and all common dimensioning standards. Drawing styles and templates are also customisable.

CAD Schroer has been a certified PTC development partner since 1998

The PTC PartnerAdvantage programme provides software partners with the tools and support they need to integrate their applications with PTC solutions to deliver value to customers and generate business opportunities and revenue growth for PTC and its partners.

M4 ISO Functionality

Unscaled

Dimensioning

Labelling

3D view

Bending tables

Breaks

Welding lists

Pipe Positions

Elevations and falls

Customisable symbols

Style templates

Genaue

Stücklisten

More functions

- Automated piping isometrics

- Configurable detailed dimensions

- Unscaled & unambiguous

- Customisable templates & styles

- Detailed parts lists

- Parts lists as tables & files

- Bend tables and welding lists

- Extendable with design notes

Directly integrated into Creo and Windchill

Pipework designs documented in line with production requirements

Automate your piping isometrics now with M4 ISO

Try before you buy with a free software trial and comprehensive advice

Contact our consultants and start your M4 ISO trial. Our consultants will advise you during your trial, enabling you to quickly generate piping isometrics to suit your specific requirements.

Start quickly with on-site workshops and training courses

In addition to standard training courses, we also offer on-site workshops, which enable you to receive tailored training while working on your first project. This guarantees you the fastest possible start into the productive use of the software.

Continuously productive and always up-to-date

Our software maintenance includes extensive support including telephone support, all software updates and access to our customer portal. This enables us to effectively support you throughout your day.

Start your free trial now or contact us for advice

If you have further questions about the software, need an offer or would like to learn more about our additional services, please contact us. Our consultants will be happy to answer any questions you may have. +44 1223 850 942 or E-Mail