AEP and MEDUSA4

“The Pipeline Layout System brings a whole new dynamic to the pipeline industry. It is a game changer. We can now handle all aspects of the design with one integrated software program, and utilize GPS to take the guess work out of pipe bending and installation. Most importantly, we can now get the job done in about a quarter of the time, and benefit from a large reduction in wasted material.”

E. Alex Paris III, President and C.E.O., Alex E. Paris Contracting Co. Inc.

AEP – a leader in pipeline construction

Alex E. Paris Contracting Co. Inc. (AEP) was established in the USA in 1928 on the bedrock principles of quality, service and dependability. The company specializes in the field of pipeline construction, and is dedicated to meeting or exceeding customers’ expectations along with maintaining the highest of standards for work place safety. With its highly skilled workforce, AEP provides a comprehensive range of services for civil and commercial projects. AEP’s principal services include utility line construction and cross-country pipeline installation. AEP also performs site development work, builds pumping stations, and installs process equipment. Together with AEP, CAD Schroer developed an innovative pipeline layout system for the design, manufacture, and installation of pipelines (Patent Pending).

The challenges when laying pipelines

AEP lays pipelines across a range of different terrains. Numerous bends and gradients need to be negotiated when laying pipelines, especially in areas of mountainous or hilly terrain. The individual pipes therefore need to be bent in a variety of ways before they are laid. They also need to be laid in an underground trench that is excavated in advance, taking into account the exact pipeline route. If a section of pipe does not fit perfectly into the trench, it has to be removed and corrected. This places additional stress on the pipe and results in delays on-site, thus increasing construction costs. The number of bends in a pipeline also has a significant impact on costs, the greater the number of bends, the greater the overall cost. The key project challenges are therefore:

- To design the optimal pipeline route having the least possible number of bends, while maintaining a minimum level of ground cover above the pipeline.

- To construct the pipeline and trench accurately, so that the pipeline always fits the trench right first time.

A specialized pipeline design tool

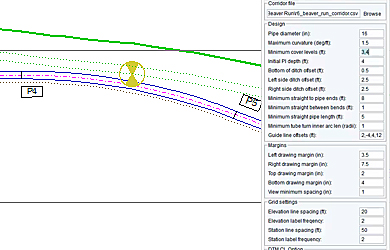

The pipeline layout system is based on CAD Schroer’s flagship MEDUSA4 2D/3D CAD software. Various custom functions were added during the development process. For example, GPS-based field-survey data of the pipe corridor is used by MEDUSA4 to produce an accurate 3D terrain model of the pipe corridor. Project-specific parameters and design rules such as pipe diameter, maximum curvature, and minimum cover level are then specified by the designer.

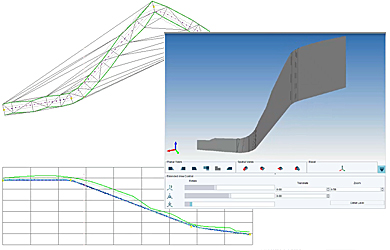

Using the terrain model and parameters entered, the software calculates a preliminary pipeline route and displays this using profile and plan views.

The designer is then able to further refine the pipe route to minimize the number of bends while maintaining the required minimum level of ground cover. The designer also specifies the lengths of pipe stock that are available to manufacture the pipeline.

When the design is complete the system automatically calculates the cut length and bending instructions for each pipe section to facilitate accurate fabrication in the field. The system then generates a 3D model of the trench bottom, which is subsequently used to control GPS-guided excavators to precisely dig the pipeline trench.

“The PLS software package gives the pipeline engineer complete control of the design at their fingertips, and produces results in real-time with pin-point accuracy.”

Armando Ferri, Senior Project Manager, Alex E. Paris Contracting Co. Inc.

More accurate planning and lower costs

Well equipped for the future

Thanks to AEP’s successful development partnership with CAD Schroer, the pipeline layout system integrated seamlessly into AEP’s operations and delivered impressive benefits from the outset, thereby quickly establishing itself as a sound investment for the future. (Patent Pending)

“We’re really excited about the pipeline layout system. We have seen great improvements in the field through the use of the software. The overall time taken for each design has also reduced to the point that our engineer can plan up to three projects at once, compared to only one prior to using the software.”

Armando Ferri, Senior Project Manager, Alex E. Paris Contracting Co. Inc.