Quality control of 3D projects

M4 PLANT – Plant Design and Factory Layout Software

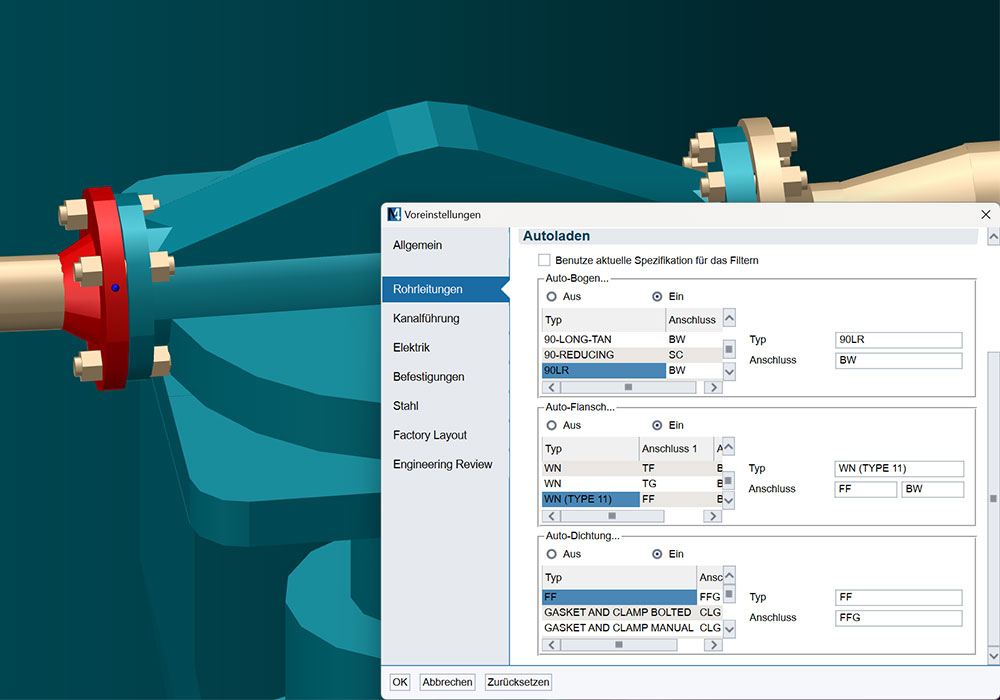

Auto selection of catalogue components

M4 PLANT has different functions to simplify the selection of suitable components from the catalogue. For example, filter criteria can be set in the catalogue browser; the system then uses these criteria to restrict the selection to relevant components. In addition, only the matching elements from the catalogue are filtered for the connection and made available to the user for selection as far as this connection is concerned. When placing the flanges or valves, the system then automatically always selects the components suitable for the line.

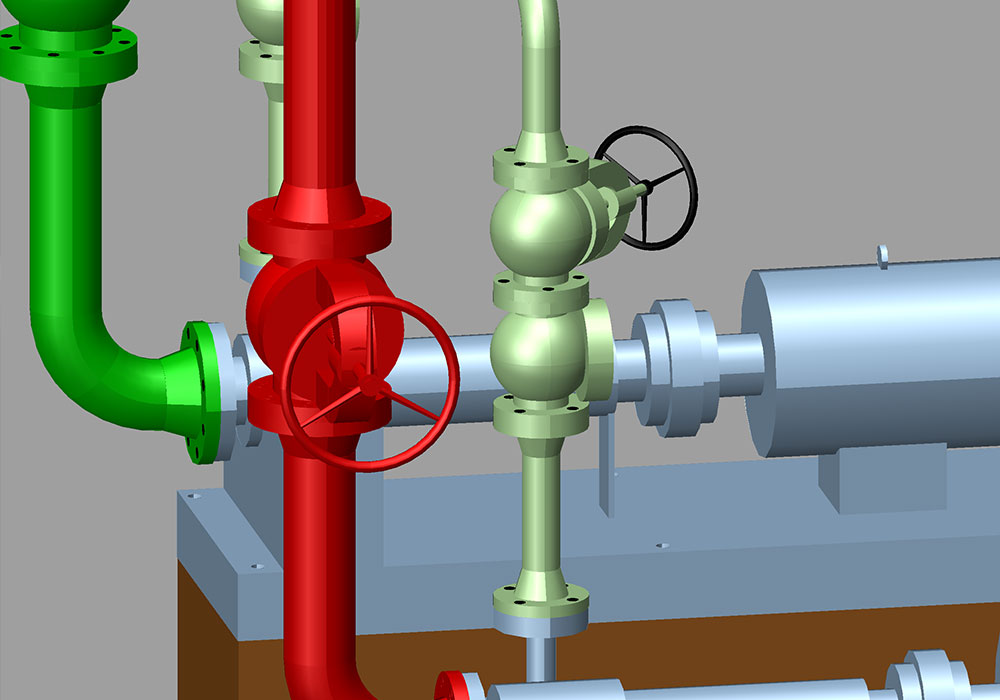

Consistency check

In order to maintain the quality of projects at a high standard at all times, M4 PLANT comprises an automatic consistency check. It continuously checks the work of individual users and warns them if they place the components, despite auto selection option, that do not match the pipeline or the connection type. Even the project planner can run a consistency check for the complete project and export it as a report to check the quality of the current planning stage.

Hard and soft collision test

M4 PLANT comprises an integrated hard and soft collision test to ensure that individual components or models do not collide with each accidentally in the 3D installation plan, or to keep subsequent free spaces for the maintenance of individual machines. It can be conducted at all times during planning and the collisions in the plan can be emphasised or exported as a report. The system also shows whether it is a hard collision, i.e. two components collide, or whether it is a soft collision, i.e. a predefined free space was violated.

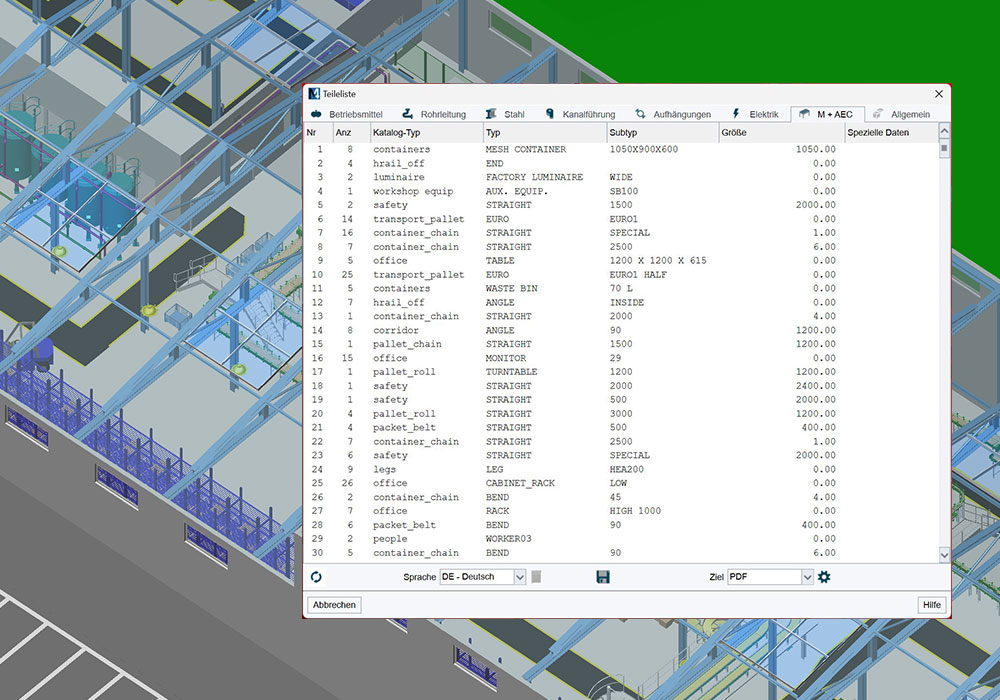

Parts lists and reports

M4 PLANT has extensive options to derive parts lists from the project data. These always contain the typical maintenance group-specific information such as the quantity, type, total length and individual segment lengths of pipelines or the quantity, individual segment lengths, weight and coating surface or steel beams. Individual attributes can be adapted as per company specifications and exported in a report. Individual parts lists or reports can be either displayed for the entire plan or only for a system, sub-system, a zone, a set or an individual selection of components. These can be naturally exported for further processing in Excel.