Conveyor and Handling Equipment

M4 PLANT – Plant Design and Factory Layout Software

Contact our consultants: by phone +49 2841 91840 or by E-Mail

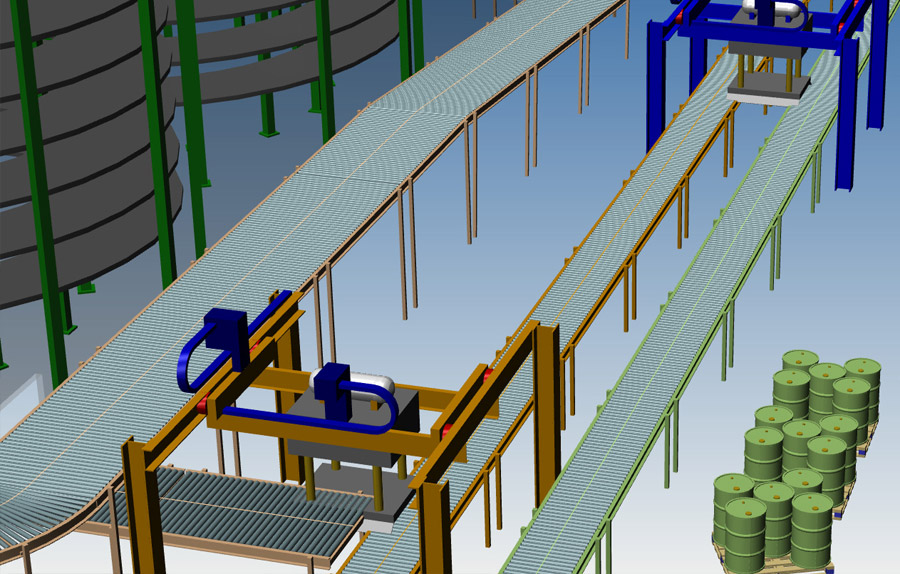

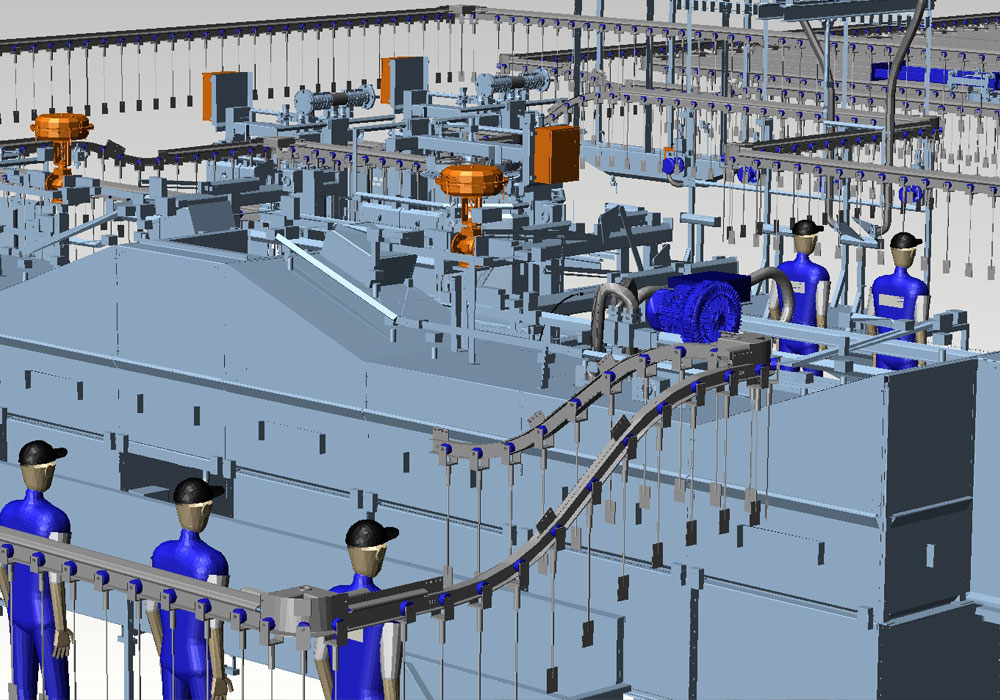

Assemble Complete Conveyor and Materials Handling Systems

The handling equipment design software Mechanical Handling is an optional software module in M4 PLANT for creating intelligent interconnected components, such as complete conveyor systems. It offers a series of configurable, user extendable catalogs of materials handling components, which can be physically interconnected to form part of an industrial process. From belt, bottle and roller conveyors to cranes, fork lift trucks, industrial racking and robots – installation designers can now easily select, lay out, configure, visualise and add intelligence to process machinery in their plant. The module also supports the controlled creation of product specials for materials handling.

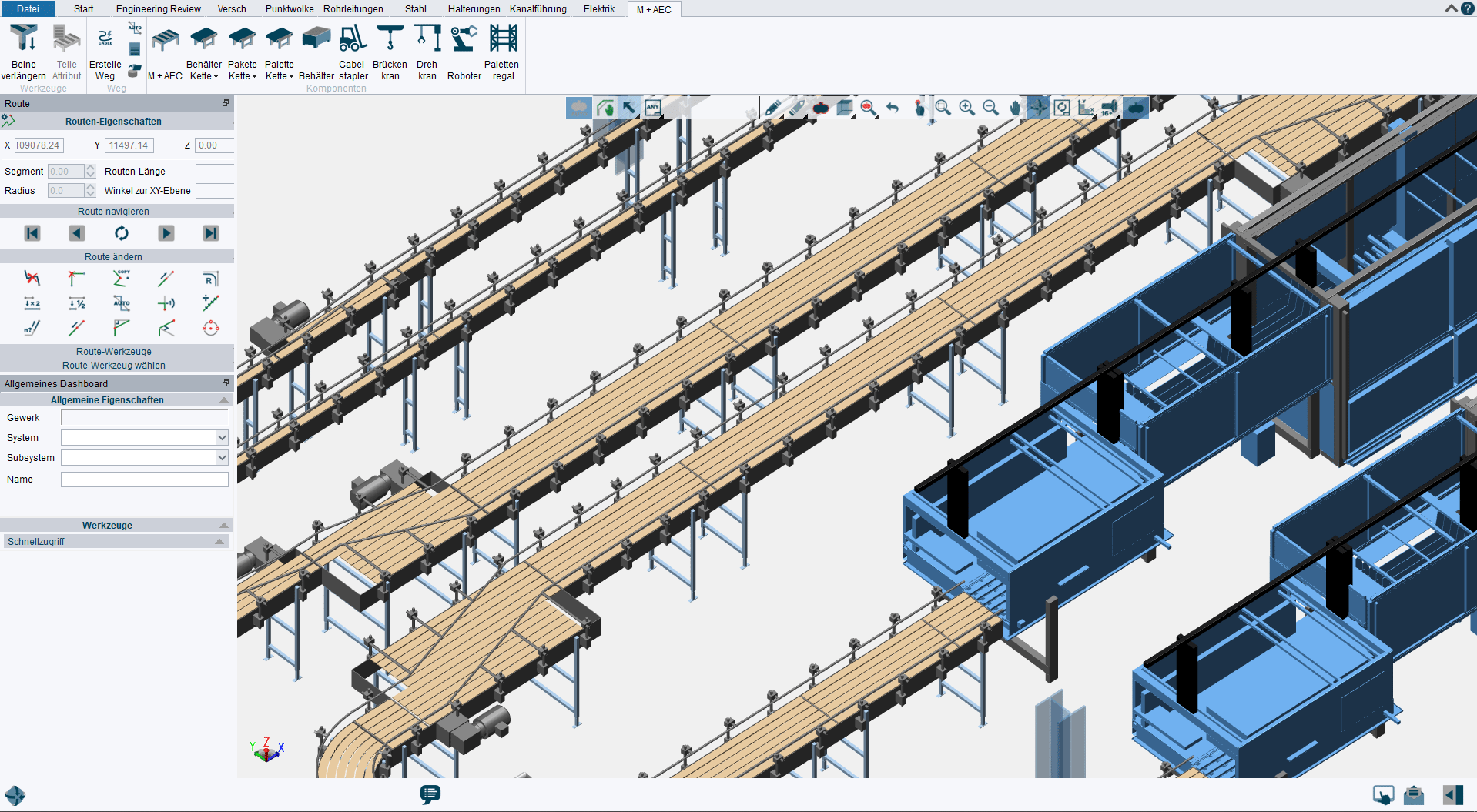

Extensive catalogues, autorouting and 2D/3D integration

M4 PLANT offers mechanical installation professionals the ability to build a complete installation electronically, with all services, prior to actual construction. Designers with the factory layout module can work interactively in a 2D or 3D environment, with automatic updates between the two. You can select and connect single components, or use a pre-defined path to auto load equipment. Accurate Bills of Materials (BOM), drawings, rule checking and interference checking are supplied as standard.

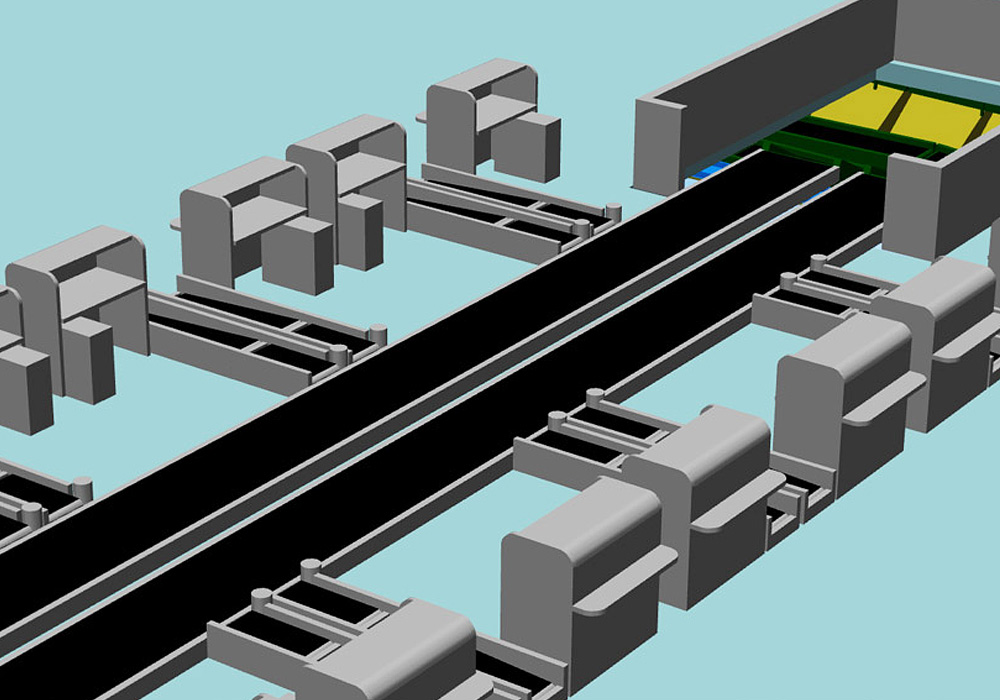

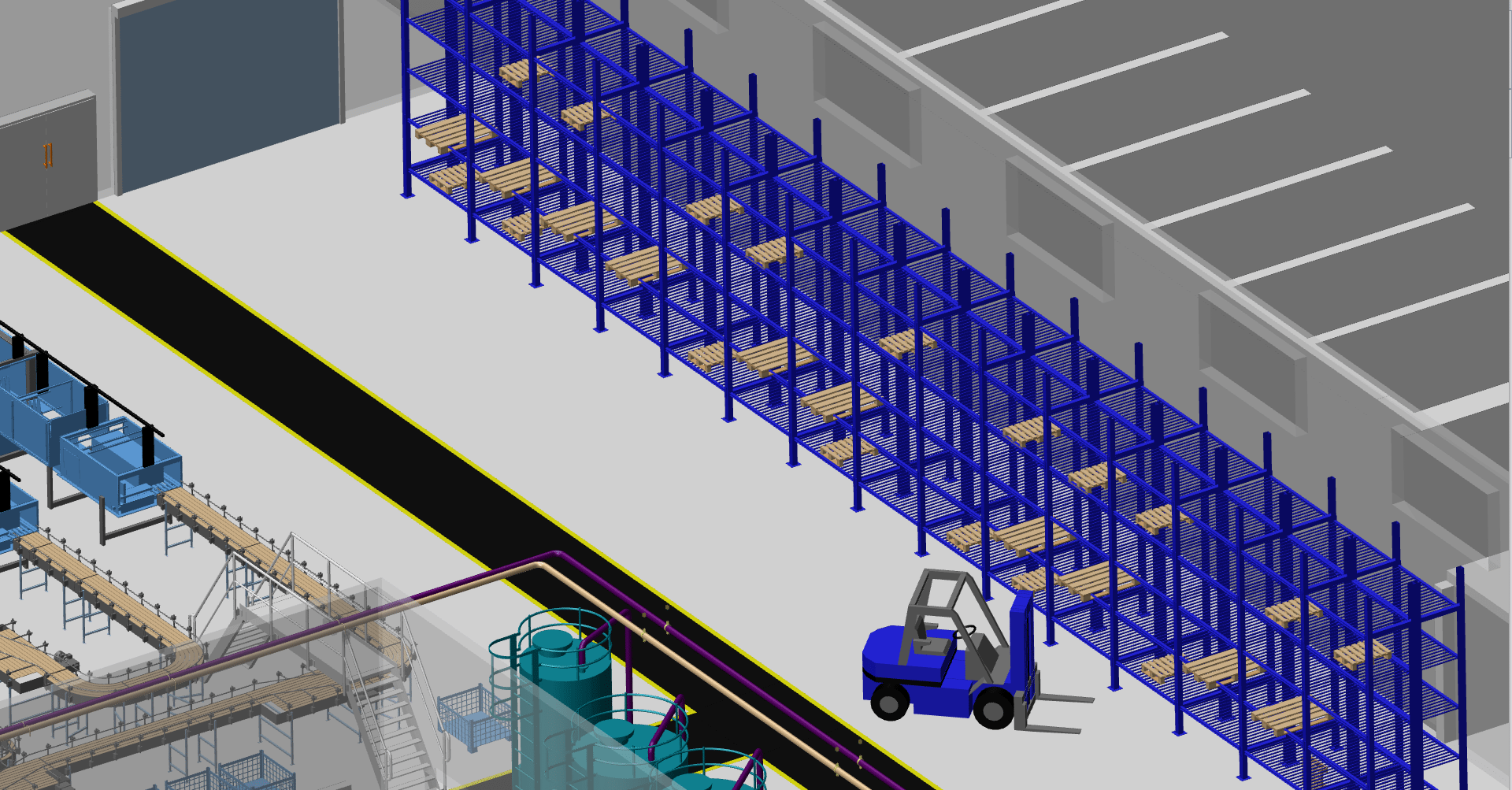

Catalog-Based Design

The 3D catalog component libraries provided with M4 PLANT MECHANICAL HANDLING help you cut down on errors, allowing you to quickly and consistently design complete handling systems based on company-specific standards.The libraries included contain many different types of belt and overhead conveyors, fork lift trucks, robots, steel and mesh containers, gantry and radial cranes, pallet racking framesand beams, to name but a few. They are user extensible and customisable, with a central database ensuring consistent delivery of up-to-date catalog data to your design teams.

Manual or Automatic Creation of Materials Handling Systems

M4 PLANT MECHANICAL HANDLING allows you to manually or automatically create your handling systems. You can select and connect single components, or use a pre-defined path to auto load equipment. The system can automatically deduce the number and required length of individual conveyor belts, for example, and auto load them along the path.

Cranes, Fork Lift Trucks and Robots

M4 PLANT MECHANICAL HANDLING provides component libraries for easily creating and animating gantry orradial cranes, fork lift trucks or robots. These catalogs can be extended to suit individual requirements. You can use the optional 3D COMPONENT DESIGNER to create your own custom parametric catalog components, for example.

Component Animation

The Animation Definition Dialog allows you to define and save animation sequences for mechanical handling components, illustrating mechanical handling processes in a plant or factory. Presentations which simulate realistic movements of machinery can serve to accurately illustrate the space required for robots to operate, or the range of movement of cranes.