Piping design:

overview, challenges and innovations

A comprehensive insight into design, current challenges and the latest technologies in piping design for a future-proof industry.

What is piping design?

Piping design is an engineering process that deals with the planning, design, construction and maintenance of piping systems. Pipelines are an essential component in almost all industrial sectors. They enable the simple and practically loss-free transport of solids, liquids, gases and vapours. Pipelines are not only used for the simple transport of media but are also an integral part of complex process systems, whether within a system, between different systems or even over long distances.

Whether in the chemical, petrochemical, food, energy or water supply industries, pipelines play a central role in practically every sector. The most important feature is their reliability, as they must guarantee the trouble-free operation of industrial plants under all circumstances. This is particularly important in highly regulated industries where safety and efficiency are top priorities.

When selecting suitable pipework materials, there are numerous high-performance materials to choose from nowadays, such as steel, stainless steel, plastics such as PVC and PE, and copper. Steel and plastic pipes are particularly popular due to their high strength, corrosion resistance and versatility and are therefore used more frequently.

The importance of pipeline construction in the various industries

Piping design plays an important role in practically all branches of industry, such as the chemical, oil and gas and food industries, as well as in building services engineering and plant construction. In the chemical industry, pipelines are often used to transport liquids and gases as well as chemical reaction products, while in the food industry, they are often used for hygienic transport.

The 6 most important industries in piping design

1. Plant engineering

In plant engineering, pipework is often used for the integration of machines and systems. Building services engineering ensures the supply of water, heating and cooling. The professional design and installation of pipelines and piping systems are fundamental to ensuring smooth and efficient process control in the various branches of the industry.

2. Chemical industry

Pipelines are particularly important in the chemical industry, where chemical substances must be transported safely and efficiently. They ensure that the right materials in the right quantities reach the right place at the right time to guarantee an uninterrupted production process at all times.

3. Petrochemistry

In the petrochemical industry, for example, pipelines transport oil, gas, and petrochemical products from the production facilities to the refineries and, from there, to the end users. To fulfil these requirements, they must be able to withstand extreme conditions such as high pressures, temperatures and corrosive media.

4. Food industry

In the food industry, pipework ensures the hygienic transport of liquids and ingredients throughout the entire production process. The pipework systems must meet the strict requirements for food safety and hygiene to ensure the flawless quality of the end products at all times.

5. Water supply and wastewater disposal

In the field of water supply and wastewater disposal, pipelines contribute to the distribution of drinking water and the collection and treatment of wastewater. They are the backbone of clean water and sanitation infrastructure and play an important role in public health and environmental safety.

6. Energy sector

In the energy sector, pipelines are used to transport oil, gas, and steam for power generation. Pipelines thus enable the transport of fuels to power plants and the distribution of energy to residential and industrial buildings, which is essential for maintaining our modern industrialised society.

All-in-one solutions for industrial piping design

Basics of pipeline construction

Defining piping design

Piping design is a central process in plant engineering that deals with the design, manufacture, installation, and maintenance of pipelines and piping systems. This process includes the installation of pipelines and all fittings and systems required for operation.

As mentioned, pipelines safely and efficiently transport liquids, gases and solids. They are used in a wide variety of industries, such as the chemical industry, the energy sector, mining, food and building services engineering.

The central task of pipeline construction is to develop and realise a suitable pipeline or pipeline system for a previously defined process (in a defined environment). An important factor in constructing such pipelines is the selection of suitable materials (in line with the requirements), such as steel, plastic or stainless steel.

The design and actual pipe laying are carried out considering factors such as corrosion resistance and pressure resistance, as well as the professional installation and commissioning of the piping system. Piping design encompasses not only the repair and maintenance of existing systems, and includes not only pipelines but also fastening systems and fittings.

History of pipeline construction

The beginning of the historical development of pipeline construction dates back up to 5000 years to antiquity. The further development can essentially be divided into five main phases:

1. Piping design in antiquity and early history

Primitive pipelines made of clay, stone or wood have been used to transport water since ancient times. Some of the best-known examples come from the ancient civilisations of Mesopotamia, Egypt, Greece and Rome.

The Romans were particularly well known for their sophisticated aqueduct system, which transported water over long distances and was used to supply cities, baths and agricultural areas.

2. Piping design in the Middle Ages

During the Middle Ages, pipelines continued to be made mainly from clay, stone or wood. However, these pipes were used to a lesser extent and were less technologically advanced than in ancient times.

3. Piping design in the 16th to 18th centuries

With increasing industrialisation and technological progress in the 16th to 18th centuries, pipelines made of metal, especially cast iron, began to gain importance.

Cast-iron pipes enabled a much more efficient water supply, especially in cities. Piping design thus contributed to the development of industrial areas and the basic water supply to the population. One of the cornerstones of this progress is the expansion of the city’s drinking water supply, which has led to an exponential increase in the population.

4. Piping design in the 19th century

The 19th century saw particularly significant advances in piping design, primarily due to the introduction of steel pipes. These pipes were very robust, durable and also suitable for transporting pressurised gases.

With the upward trend in pipeline construction, the global population is also growing, and the demand for urbanisation and construction projects is increasing. In the construction materials market, there is a high demand for necessary residential, commercial and industrial applications.

The development of pipework systems played an important role in the spread of gas and water supply systems in urban areas, as well as the development of new resources in remote areas, such as oil fields.

5. Piping design in the 20th century and up to the present day

In the 20th century, modern materials such as plastics and composites were introduced for piping design, resulting in lighter, corrosion-resistant and more cost-effective piping.

Advances in technology, such as automated welding processes and advanced monitoring and control systems, have made the construction and operation of pipelines safer, more efficient and more environmentally friendly.

Nowadays, pipelines are used not only for the supply of water, gas and oil but also for the transport of chemicals, food, wastewater, geothermal energy production and district heating.

There has been a continuous development of pipelines and piping systems from antiquity to the present day, with new materials and technologies constantly improving the performance and efficiency of pipeline construction.

All-in-one solutions for industrial piping design

The different types of pipework construction

There are different types of pipeline construction, including above-ground, underground and open construction methods. Above-ground construction is used in the construction of industrial plants. It consists of pipelines mounted on supports or frames that carry the pipeline, while underground construction involves laying pipelines in trenches or tunnels.

Construction methods in piping design

Pipe systems laid above ground

Non-buried pipelines are used in various industries in plant construction industries, including water supply, wastewater disposal, oil and gas extraction, and chemical and petrochemical industries to transport media safely and efficiently over long distances. When designing such piping systems, for example, thermal insulation measures must be taken to ensure the efficient transport of liquids or gases and to prevent possible corrosion damage. The choice of suitable materials and coatings, as well as adaptation to local conditions, are crucial to ensure the reliability and longevity of non-buried pipelines.

Underground pipe systems

Underground pipelines play a crucial role in the infrastructure of modern societies. They are used for the safe and efficient supply of drinking water, the removal of wastewater, the distribution of district heating and district cooling and the laying of telecommunication cables. Underground pipelines are mainly used in water supply, wastewater disposal, district heating and cooling and telecommunications to transport media or cables safely underground. In the case of underground pipelines, additional considerations are required in individual cases, such as consideration of earth loads, expansion behaviour in the ground or subsidence effects. These factors must be taken into account when designing underground pipelines. Due to their invisible presence underground, they make a significant contribution to maintaining the quality of life and economic progress by ensuring a reliable supply and, at the same time, protecting the environment.

Depending on the application, however, there are also very specific construction methods, such as laying in open trenches, horizontal drilling or pipe jacking to install pipelines. The selection of the most suitable method depends on factors such as terrain, environmental conditions and cost-effectiveness. The correct pipe bedding and insulation are also important to ensure the stability and longevity of a pipework system.

The importance of the individual sectors in piping design

Pipelines are used in a wide variety of industries, such as the chemical, oil and gas, food and water treatment industries. In the chemical industry, they are used to transfer raw materials as well as primary and end products. The oil and gas and petrochemical products. The chemical, oil and gas, and pharmaceutical industries are highly dependent on optimised piping system design. Errors here can quickly become dangerous or harm production. The food industry uses pipework for the hygienic transport of liquids and ingredients of all kinds. In water treatment, they contribute to the distribution of drinking water and wastewater disposal.

Design of piping systems

The basic steps in the design process

Step 1: Needs analysis and requirements

The first step in the design of pipework is a precise requirements analysis. This involves determining the specific requirements for the pipework system. This includes factors such as

- Definition of the entire process of the planned pipework system

- Close attention to the surroundings to include them in the design as early as possible

- Type and quantity of the medium to be transported (liquid, gas, solid)

- Required volume flow and pressure

- Temperature and corrosion resistance of the material

- Space conditions and accessibility at the installation site

- Pipeline design with 3D CAD systems

- Calculate material costs based on the parts lists to be created

- Observe legal regulations and standards

- Operational safety and service life

- Compilation of all important documents for production and assembly

Based on this analysis, the specific technical requirements for the pipework system can be defined.

Step 2: Route planning and terrain analysis

The next step involves precise route planning. This involves determining the optimum route for the pipeline, considering factors such as terrain topography, buildings, infrastructure and accessibility. A precise analysis of the terrain is important here to recognise obstacles early and avoid conflicts with other pipelines or structures from the outset. Aspects such as earthquake safety and the risk of landslides or flooding are also included in the route planning, along with numerous other aspects.

Step 3: Conceptualisation

Concept drawings or models are now created based on the requirements analysis and route planning. These contain an overview of the planned pipeline route, the materials, valves and fittings used and the connections to upstream and neighbouring systems. The concept drawings serve as the basis for further detailed planning.

Step 4: Detailed planning

The concept drawings or models are further elaborated in the detailed planning stage. This is where the exact dimensions of the pipework, pipe sizes, wall thicknesses and materials, as well as the positioning of fittings, moulded parts and brackets, are determined. Aspects such as thermal insulation, corrosion protection and ease of installation are also considered in the detailed 3D design.

Step 5: Calculation of material requirements and costs

Finally, the exact material requirements are determined based on detailed planning. This includes pipes, fittings, valves, seals and fasteners. Taking delivery times and prices into account, the total costs for materials, installation and commissioning are calculated. This calculation forms the basis for budget planning and tendering for the pipework project. This is usually done using parts lists provided by an advanced solution for the 3D pipework design.

The order of design is crucial

The order in which piping systems are designed is of crucial importance, as it allows all relevant factors to be taken into account precisely during the design process.

The 5 steps for designing pipework systems in the correct order:

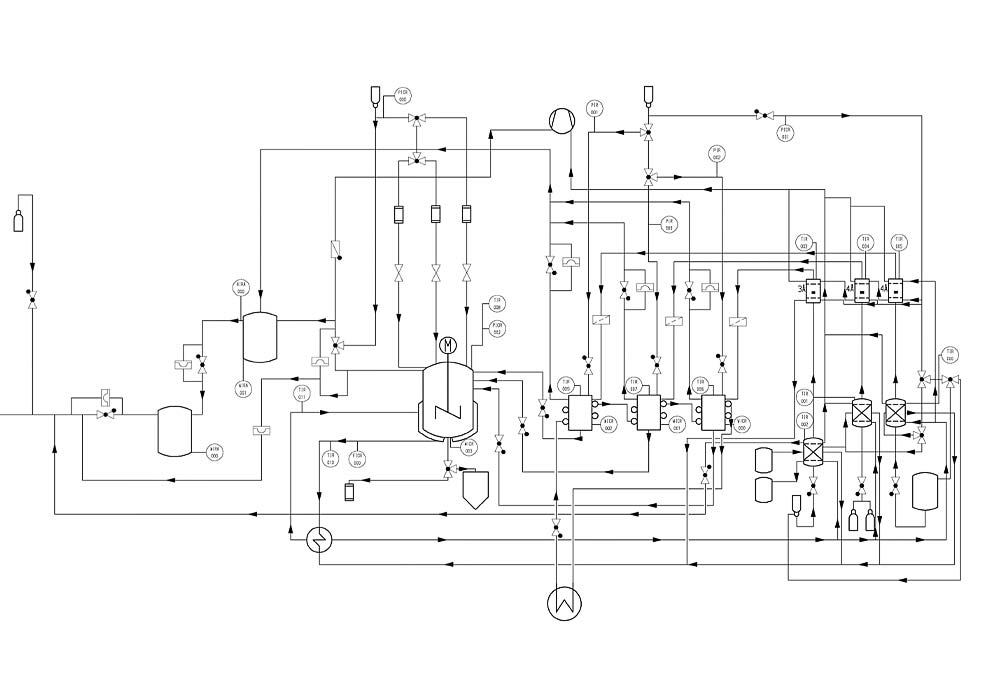

1. Create P&ID diagrams (pipework and instrument flow diagrams)

- The first step is to define the entire process for the pipework system

- P&ID software is a helpful support here

- These schematic diagrams show the routing of the pipework and the arrangement of all the necessary instruments and systems.

- The P&ID diagram shows a clear pipework system and how it works in a simplified flow diagram.

- The P&ID diagram serves as a basis for further planning steps and helps to define the pipe route and the placement of fittings and instruments.

2. Capture environment

- Capture all existing data of the environment, such as terrain data, 2D floor plans, 3D models or laser scans

- All of this can be used to visualise the terrain and buildings in the project in detail.

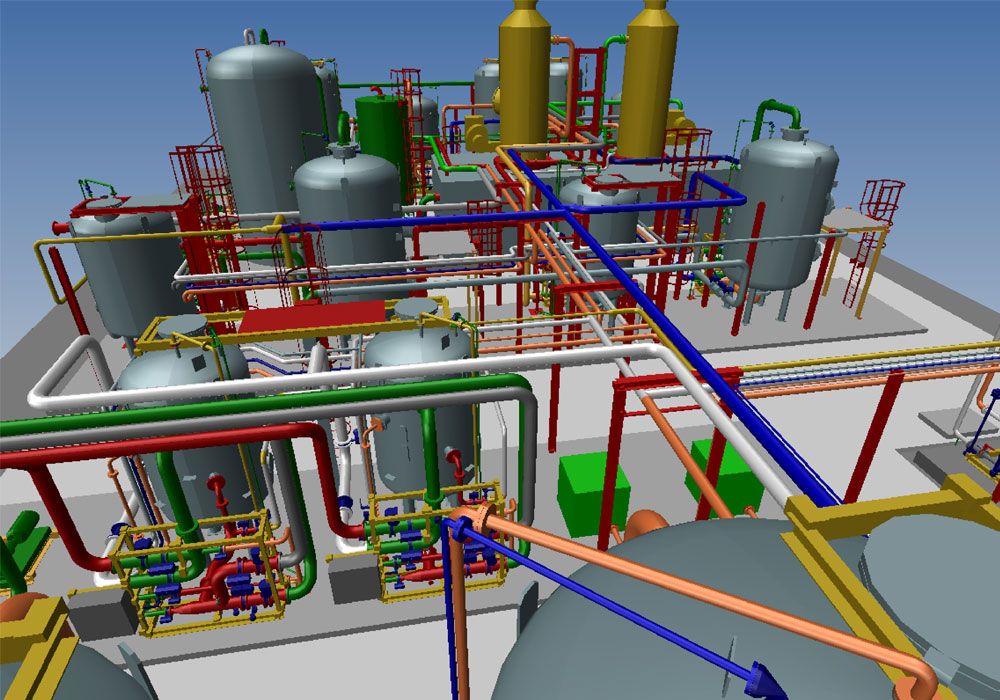

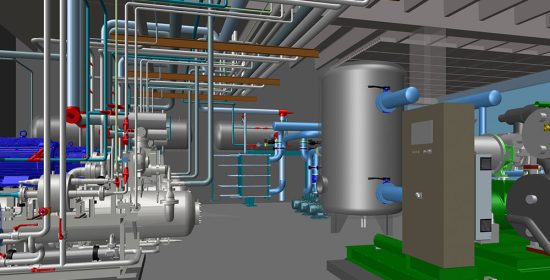

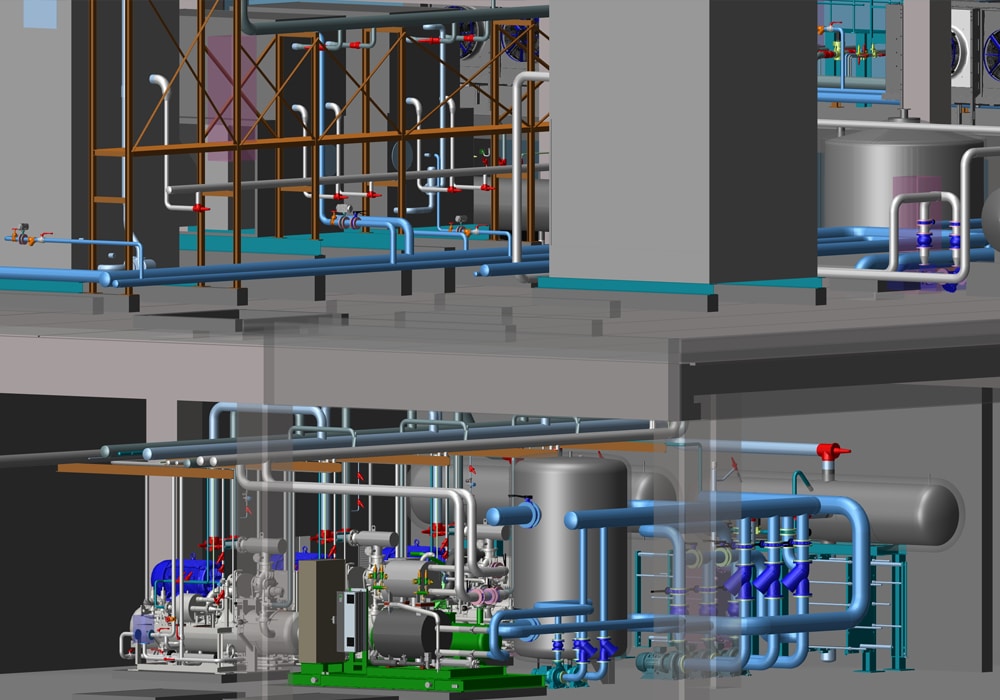

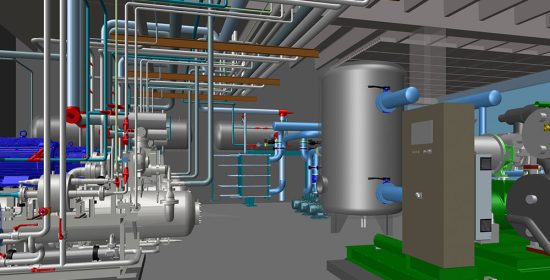

3. Generate 3D design

- The 3D design enables a detailed visualisation of the piping system with all associated components in a virtual model.

- Specialised piping design software is used to complete these tasks in the shortest possible time

- 3D pipework construction software has the right functions for all difficult and time-consuming design tasks

- Autorouting tools or the automatic placement of suitable bends or flanges provide support for precise layout and detailed design

- Modern 3D design identifies potential conflicts, such as collisions with other system components and helps optimise the layout.

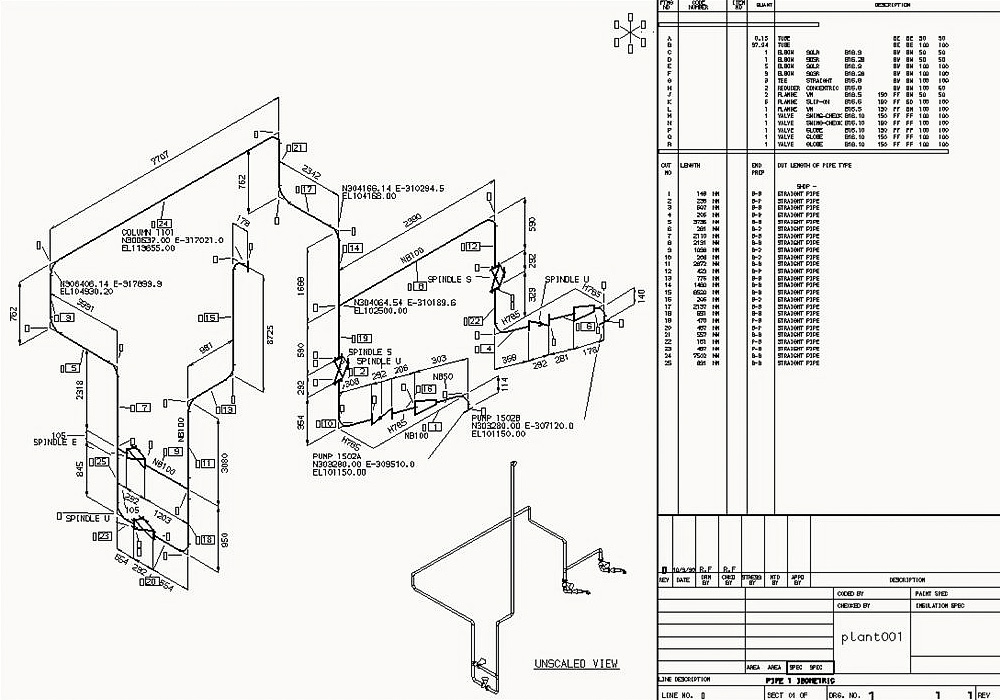

4. Automatically generate pipework isometrics

- Pipe isometrics are detailed drawings showing the pipework’s exact route in all three dimensions.

- Piping isometrics are a valuable tool for documentation and quality control.

- Such isometrics provide a precise representation of the pipework geometry and help with the production and installation of the pipework on site.

- The generation of pipework isometrics benefits from the previous 3D design, as pipework isometrics can be created with the software at the click of a mouse.

- In advanced planning systems, pipework isometrics are automatically generated from the previously created 3D design.

5. Parts lists

- Parts lists contain a list of all components and materials required for the construction of the pipework system.These lists serve as a basis for procuring materials, creating construction orders and supporting cost calculation and scheduling.

- If steps 1 to 3 have been carried out consecutively and with suitable software, this step is completely automated.

- 3D pipework construction software not only includes all the associated parts lists and welding tables but also contains all the data for the pipe bending machines.

- Modern plant and pipework construction systems generate parts lists with all components, pipes, fittings, and instruments for the plant, which are just created at the touch of a button.

Piping Design with 3D layout, P&ID, Piping Isometrics, Building design and much more in one comprehensive package. Benefit from the many advantages of advanced functionality and great service.

Technical requirements in piping design

A pipework system’s most important technical requirements include stability, tightness, corrosion resistance and material compatibility. It must be able to withstand operating pressures and temperatures and always ensure the safe and efficient transport of media. In addition, conformity to standards, fire protection, and environmental compatibility are important factors for the safety and sustainability of the systems and should not be neglected. Customised solutions always take into account the specific requirements of the various industries and areas of application.

Piping and P&ID (piping and instrument flow diagram)

The importance of P&ID diagrams in pipework technology

P&ID diagrams provide a very good graphical representation of the pipework and all instrument connections. They show the structure and flow of the process media as well as the placement of instruments and control elements. These diagrams are important for understanding the overall system and serve as a basis for piping system design, construction and maintenance.

What is a flow chart and how can I create one quickly and without errors?

Integration of pipework in P&ID diagrams

Pipelines are represented in P&ID diagrams by lines showing the media’s flow to be transported. They are connected to instruments such as valves, pumps and measuring devices to control and monitor the process flow. The integration of pipelines in P&ID diagrams enables comprehensive and simple visualisation and analysis of the entire process flow.

Use of P&ID diagrams for design and documentation

P&ID diagrams are used throughout the life cycle of a piping system in a plant, from design and construction to commissioning and maintenance. Such diagrams serve as a reference for engineers, technicians and operators and support the documentation of plant modifications and improvements. P&ID diagrams are indispensable tools for efficiently managing and maintaining piping systems.

Pipelines in 3D

3D modelling in pipeline design

3D modelling plays an immensely important role in designing and constructing a modern piping system. With the help of powerful 3D plant engineering software, piping systems can be designed and visualised in three dimensions. All relevant components, such as pipes, fittings, valves and brackets, are precisely positioned and linked. 3D models enable a realistic visualisation of the entire piping system and serve as the basis for further design and production.

Advantages of 3D models in design and visualisation

The use of 3D models offers numerous advantages in the design and visualisation of piping systems. The three-dimensional visualisation of the piping system allows a precise check of feasibility and freedom from collisions as early as the planning phase. In addition, such 3D models enable realistic visualisation, which gives everyone involved a better understanding of the project. Furthermore, 3D models facilitate coordination with other trades and disciplines, as potential problems can be recognised and solved very early.

Pipelines and pipeline isometrics

Introduction to pipework isometrics

Piping isometrics is a special form of visualisation used in designing and constructing piping systems in plants. The route of the three-dimensional pipework and the individual elements of the pipework are depicted as symbols in a two-dimensional drawing in an isometric view. This illustration contains numerous details, such as the length, width and height of the pipework as well as all installed instruments and apparatus. A pipework isometric view is dimensioned but is shown to scale, which means that even very complex or long pipework can be depicted in detail.

The piping isometry enables precise visualisation of the piping route and serves as an important basis for the production and installation of the piping system.

Use of pipework isometrics in design

Isometric drawings can precisely design and document pipework routes, connection points, and component positions. They also serve as the basis for creating parts lists, material calculations and production documents.

The advantages of automatic isometric generation compared to manual generation >>

Importance of pipework isometrics in production and installation

Isometric drawings are essential for the production and installation of pipework systems. They provide fitters with detailed information on pipe lengths, angles and connection points, allowing precise cutting, bending and positioning of the pipes. Isometric drawings also serve as a reference for documenting the pipework route and facilitate subsequent maintenance and servicing work.

Detailed parts lists

Parts lists are usually created in the design department. This is where the drawings for new products and the list of all required individual parts are created. It is possible to create parts lists automatically based on CAD data. Here, it depends on which data is available.

Parts lists in P&ID design

When planning flow diagrams, modern software solutions can already be used to generate parts lists from the design. However, these only contain information about the type of components or pipework. Bends or flanges are not yet included in the planning and are, therefore, not included in the parts list.

Parts lists in 3D design

In addition to the components from the P&ID planning, further details, such as the exact length of the pipework and the type of components, such as valves, flanges, screws or bends, are also included in the 3D design. These are then all listed in detail in the parts list.

Parts lists in the pipework isometrics

With integrated design, the pipework isometrics are automatically generated directly from the 3D CAD data. This means they also contain the full scope of information for the respective pipework. This can also include welding lists or bending tables, which may also be relevant for production.

Piping Design with 3D layout, P&ID, Piping Isometrics, Building design and much more in one comprehensive package. Benefit from the many advantages of advanced functionality and great service.

The construction phases in piping design

Preparatory work, pipe laying, connections and welding work

- The construction phase begins with a detailed analysis of the system layout and process requirements.

- Site preparation

- Selection and procurement of special pipe materials that meet the requirements of the respective system.

- Installation of the pipework in accordance with the technical drawings and specifications.

- Laying the pipework system, which includes:

- Considering height differences, bends and connections

- Carrying out numerous welding operations to join the individual pipe segments together, thus creating a continuous pipework system.

- Quality control

- All welding work must meet strict quality standards to ensure that the pipework always functions safely and efficiently.

Quality control during construction

Comprehensive quality checks are carried out during construction to ensure that all work meets the applicable standards and specifications. These checks include, for example, a detailed inspection of the weld seams, dimensional tests of the pipes and a review of all installation processes. Quality control is essential to the construction process as it helps recognise and rectify potential defects early. Regular inspections and tests can thus guarantee the safety, reliability and performance of a piping system.

Industrial piping design

In industrial piping design, specialised techniques and processes are used to construct piping systems for complex industrial applications. These processes often involve high-performance materials, particularly stringent quality controls and compliance with strict safety standards. Industrial piping design requires a deeper understanding of the requirements of different industries and the ability to develop customised solutions. Close cooperation with engineers, architects and other professionals is important to ensure the success of piping construction projects in industrial environments.

Process engineering: Complete overview with examples and tips

Special applications in pipework construction

When constructing new plants, special types of piping design need to be considered. Special conditions, hazards, regulations and codes of practice must be taken into account.

Oil and gas pipes

Pipelines play a central role in transporting oil and gas. Modern high-pressure pipelines enable these energy sources to be transported safely over long distances. Corrosion-resistant steel pipes that can withstand extremely high loads are used for this purpose. Additional safety devices, such as shut-off valves and monitoring systems, ensure safe and reliable operation at all times.

Water supply

In the drinking water supply, pipes ensure the distribution of water from the waterworks to the end consumer. Plastic or stainless steel pipes that are food-safe and meet all hygiene requirements are usually used in the water supply. In addition, such pipes must also withstand high pressure and high temperatures and be corrosion-resistant.

Sewage systems

Pipelines are also used for the disposal of wastewater. These sewer systems transport wastewater, rainwater and industrial wastewater to sewage treatment plants. Such pipes must be able to withstand chemical loads and contamination. Concrete, plastic or vitrified clay pipes are often used for wastewater systems.

Piping design in the pharmaceutical industry

In the pharmaceutical industry, pipework is essential for transporting high-purity media such as pharmaceuticals, chemicals and ultrapure water. Particularly, high-quality stainless steel and plastic pipes are used here, which fulfil the highest purity requirements.

Piping design in the chemical industry

Chemical production plants rely on a complex network of pipework. Such pipework systems transport aggressive chemicals, acids and alkalis, often pressurised at high temperatures. For this reason, corrosion-resistant materials such as stainless steel, plastic or ceramic are used to withstand extreme conditions.

Industrial applications

Many pipework systems are used in a wide variety of industrial applications, including the food, energy or refrigeration industries. They fulfil tasks such as transporting process media, solids, coolants or steam. Depending on the application and requirements, various materials and designs are used.

Technological advances in piping design

Automation and robotics

Automation and robotics have enabled numerous important advances in piping design. Automated machines can now perform complex tasks such as cutting, bending, and welding pipes, dramatically increasing productivity and significantly reducing the error rate. Robotic arms are also used for precision welding, improving the quality of joints. These technologies enable faster and more efficient completion of pipework systems and also help to reduce overall costs.

Digitisation and use of XR

Digitalisation has also led to a revolution in piping design by providing numerous advanced design and simulation tools. Building Information Modelling (BIM) enables a comprehensive virtual representation of piping systems, leading to better design, collision detection and resource optimisation. The use of extended reality (XR), including virtual reality (VR) and augmented reality (AR), allows designers to visualise and review complex piping systems in an immersive environment before they are built. These techniques significantly improve accuracy and efficiency during the construction process.

New materials and technologies

Developing new materials and technologies has greatly improved the performance and durability of piping systems. High-strength plastics such as polyethylene and polyvinyl chloride are increasingly used for piping design as they are lighter, more corrosion-resistant and more cost-effective than materials used in the past. Advances in coating technology offer improved protection against corrosion and abrasion, extending the pipes’ service life. In addition, innovative joining technologies, such as electromagnetic induction and bonding techniques, enable faster and more efficient installation of pipework.

Challenges in piping design

Complexity of design and construction

The design and construction of piping systems is a time-consuming and highly complex task. Numerous factors, such as the type of media, pressure, temperature, corrosion resistance, and space conditions, must be taken into account. Added to this are safety regulations, standards and authorisation procedures, which must be adhered to at all costs. Furthermore, pipework in industrial plants requires precise coordination with other trades to avoid problems. This level of complexity places high demands on the technical expertise and coordination skills of planners and designers.

Integration of 3D models and P&ID diagrams

3D modelling and P&ID diagrams (piping and instrumentation diagrams) are becoming increasingly important to do justice to the complexity of pipeline construction. The three-dimensional representation enables a realistic visualisation of the entire piping system, making it easier to check its feasibility and collision-free nature as early as the planning phase.

P&ID diagrams also provide detailed information on pipework routes, fittings and the instrumentation used. However, the integration of these planning tools poses a certain challenge, as they require some investment in software and staff training. Only by seamlessly linking 3D models and P&ID diagrams can the complexity of pipework construction be effectively mastered and a consistent planning workflow ensured.

Challenges in the realisation of piping isometrics

The precise creation of piping isometrics can be a major challenge in piping design. These two-dimensional representations of three-dimensional pipework routes must accurately record all lengths, angles and connection points. Even the slightest inaccuracies can lead to considerable problems during installation and commissioning.

In addition, seamless integration of isometrics into other planning tools, such as P&ID diagrams, requires a certain amount of coordination. However, this is the only way to avoid media discontinuities and ensure a consistent planning workflow. It is clear that the precise implementation of piping isometrics is a key task in piping design, which places certain demands on both design and execution.

With 3D pipe planning software, creating precise pipework isometrics is no longer a major challenge. This is where early 3D design comes in, allowing pipework isometrics to be generated with just a click of a mouse.

Calculation of material requirements and costs

The exact material requirements for pipes, fittings, valves, suspension, and fastening systems must be determined based on the design and construction data. This determination requires extensive calculations and empirical values to avoid over- or under-ordering. At the same time, the total costs for materials, installation, and commissioning must be precisely calculated to ensure the project’s economic viability.

Errors in the calculation can lead to considerable cost increases and jeopardise the project’s implementation. Therefore, the use of state-of-the-art planning tools, precise execution and careful costing is very important to overcome such hurdles and realise successful piping projects.

Outlook for the future of piping design

Trends and developments in piping design

Piping design faces numerous new trends and developments that will shape the industry in the coming years. Six of the most important trends for the coming years are listed below:

The 6 most important trends in piping design

- Climate Friendliness: Increased use of environmentally friendly materials and manufacturing processes to reduce the ecological footprint.

- Latest Technologies for Design: Advancing digitalisation through the use of technologies such as artificial intelligence and machine learning to optimise planning and construction processes.

- Latest Technologies for Production: Increasing importance of innovative manufacturing technologies such as 3D printing, which enable the production of customised piping components and significantly increase manufacturing efficiency.

- Smart Intelligence: Introduction of intelligent pipework systems with sensors to continuously monitor condition and performance and enable predictive maintenance.

- New Materials: Use of advanced materials such as nanotechnology-based coatings and composite materials to improve the corrosion protection and robustness of pipework.

- New Construction Methods: Innovative construction methods, such as the use of modular construction elements and autonomous construction robots, to increase the efficiency of the construction process and improve safety in the workplace.

Potential innovations and technologies

Innovations and new technologies promise to drive piping design forward and transform the industry. One promising development is the introduction of intelligent piping systems, which are equipped with sensors to continuously collect data on the condition and performance of piping systems. The data obtained can then be used for predictive maintenance to prevent breakdowns and extend the service life of the systems.

Furthermore, advanced materials such as nanotechnology-based coatings and composite materials could improve corrosion protection and thus increase pipeline reliability. In addition, innovative design and construction methods, such as the use of modular construction elements and autonomous construction robots, can significantly speed up the construction process. It is clear that piping design is facing an interesting but also challenging transformation that will be characterised by a variety of trends and innovations.

Conclusion

Summary of the most important points

Pipelines are essential components in a wide range of industries, enabling the safe and efficient transport of liquids, gases and vapours. From the chemical and petrochemical industries to the food, energy and water supply sectors, pipework plays a central role in today’s world.

The history of pipeline construction spans various development phases, from ancient times with primitive pipelines made of clay and wood to modern steel and plastic pipes, impressively emphasising the importance of piping systems. Today, technologies such as automation, 3D modelling and digital planning tools enable more precise and efficient pipeline construction than ever before.

The design of piping systems involves various steps, from analysing requirements and planning routes to creating detailed drawings and cost estimates. Integrating piping in piping and instrument flow diagrams (P&ID diagrams) and using 3D models and piping isometrics facilitate design and visualisation.

Despite the numerous advances in piping design, many challenges remain today. However, by utilising new materials, technologies and planning methods, these challenges can be overcome to ensure a reliable and efficient design and, ultimately, construction of piping systems.

Outlook on the importance of piping design in the future

Piping design will continue to play a very important role in practically all industrial sectors in the future. Looking to the future, a number of trends and developments are foreseeable that will characterise the construction of modern piping systems.

5 trends that will influence the construction of pipework in the future:

1. Sustainability and environmental awareness:

As environmental awareness grows, piping systems will increasingly be designed to meet increased environmental requirements. This could include, for example, using materials with a lower environmental footprint, such as recycled plastic or biodegradable materials. In addition, energy-saving technologies and more efficient process pipework will become increasingly important to reduce the consumption of resources.

2. Digitalisation and Industry 4.0:

Digital technologies will revolutionise piping design. From design to production and maintenance, digital tools such as Building Information Modelling (BIM), Internet of Things (IoT) and artificial intelligence (AI) will play a central role. Using such technologies will result in improved efficiency, accuracy and cost control throughout the entire life cycle of piping systems.

3. Modularity and flexibility:

Future pipework systems will likely be more modular and flexible to better adapt to changing requirements and environments. This could include the use of prefabricated modules and flexible connections to enable faster installation and, therefore, faster customisation.

4. Safety and reliability:

In view of the increasing demands on safety and reliability, future pipework systems will increasingly rely on preventive maintenance and monitoring. Sensors and monitoring systems will be integrated to detect potential problems early on and thus minimise failures.

5. Integration of renewable energies:

With the increasing transition to renewable energies, piping systems will play an important role in transporting biomass, hydrogen, solar heat and other renewable energy sources. Such a transition will require developing specialised piping systems and adapting to the existing infrastructure.

Piping design will continue to play a key role in supporting various industrial sectors and overcoming global challenges in the future. Integrating sustainability, digitalisation, modularity and renewable energies will shape the sector and further strengthen its importance for modern infrastructure.

FAQ – Piping design

Piping design is the engineering process that includes the planning, design, construction and maintenance of piping systems. These systems enable the loss-free transport of solids, liquids, gases and vapours.

Pipelines are central to many industries, including chemicals, petrochemicals, food, energy and water supply. They ensure the safe and efficient transport of raw materials, intermediate and end products.

Depending on the requirements and application area, pipework systems must be stable, leak-proof, corrosion-resistant, and material-compatible. They must withstand operating pressures and temperatures and work safely and efficiently. Other important factors are conformity to standards, fire protection and environmental compatibility.

The most important industries that benefit from piping design are plant construction, the chemical industry, petrochemicals, the food industry, water supply and wastewater disposal and the energy sector.