Revolutionise your P&ID designs with the help of a modern software package

One of the first tasks when designing process plant is the creation of P&IDs (process & instrumentation diagrams). Depending on the tools used, the design time required and the quality of the results varies.

Unnecessary work during P&ID design

Many businesses use outdated methods to produce their P&ID flowcharts. The work is performed either on paper or with a rudimentary software package. The end result is often just a pictorial diagram, without any underlying intelligence. Consequently, parts lists have to be produced manually, which provides scope for human error to occur. A high degree of checking is therefore usually required to ensure an acceptable level of quality is achieved.

Stay competitive

Many plant engineering companies wonder why they fail to win contracts. Their competitors’ offers arrive at the customer without delay, the design quality is precise, and the documentation looks first-class. What do they do differently to achieve this, and why are they faster and better than your own business? The answers can often be found in the tools they use and the automated processes they deploy. Early investment in emerging technologies is often the key to competitiveness.

Investing and adapting processes

When business levels decline, and the competition starts to overtake, decisions are often taken to reduce the level of investment in the business. Contrary to expectations, this is actually the time to see what must be improved to reach the quality desired by customers. Two factors can usually be adjusted with a modest investment: the tools used and the related work processes.

Investment in specialised software pays dividends

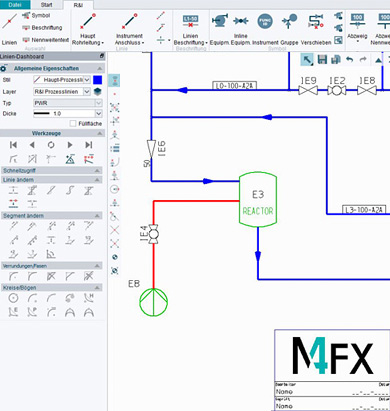

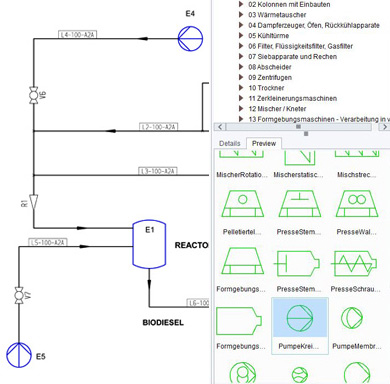

Specialised software tools now exist for P&ID work. Not only do these tools enable the creation of P&IDs, they also offer functions to accelerate the project flow. Symbols and symbol groups are loaded from catalogues and connected with pipelines. During the layout process, the system checks the completeness and correctness of the P&ID design. Built-in layout rules ensure that P&IDs are clearly legible. This reduces the time and effort required for every project, leading to a rapid return on investment.

Develop leaner processes

In addition to the creation of P&IDs, the plant design process requires the creation of various associated listings to support downstream tasks. For example, accurate parts lists are required to facilitate procurement. With a lean approach, the P&ID software automatically generates all required listings such as valve schedules, parts lists and line lists. The benefits of utilising a lean process means the investment in suitable P&ID tools pays back in an even shorter time.

What P&ID software for plant design should provide

Modern P&ID software must include certain key functionality to be suitable for process design. It must contain comprehensive symbol catalogues to ensure designs can be produced to current standards. The catalogues must be adaptable so as to incorporate customer-specific symbols where required. The software must also support the placement of entire P&ID assemblies.

In addition, professional P&ID software offers the potential for integrated error checking. At each step, the user is provided with feedback regarding the quality and legibility of the design. Using dynamic adjustment tools, the user is able to adjust the layout of the P&ID without adversely affecting the overall design integrity.

One of the greatest advantages for everyday work is the automatic creation of listings. The fact that accurate parts lists are automatically available immediately after the creation or modification of a P&ID saves considerable time for the project. Together, all the advantages add up to a considerable competitive edge.

Download intelligent P&ID software and get started today

One of the leading P&ID products on the market is M4 P&ID FX. It provides a wide range of functionality for intelligent P&ID design. It also comes with extensive, pre-defined, standards-based symbol catalogues, and offers consistency checking and automatic parts list generation. Users can also add their own custom symbols using the supplied 2D drafting tools. Support for industry-standard interfaces ensures data can be exchanged with both customers and suppliers.

A downloadable free trial version and detailed video tutorials are also available to help you get started and assess the benefits it can bring to your business.