WSP CEL & MPDS4: Delivering Uncompromising Process Plant Expertise

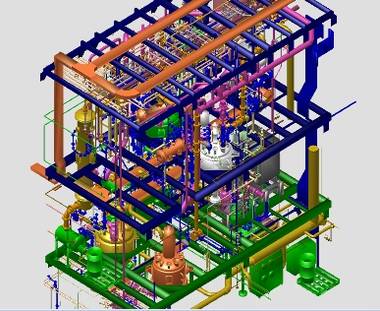

“CEL International* provides world class services in support of capital investments in the pharmaceutical and process industry. We support everyone from ‘start-ups’ to major multi-nationals, providing consultancy, design, engineering, procurement, construction/project management and validation services to customers whose facilities incorporate technical complexity. The MEDUSA4 PLANT DESIGN SYSTEM (MPDS4) is our product of choice in the complex process plant design and layout arena. The software supports the flexibility we need as we address diverse engineering challenges in a multitude of market sectors. We are well known for delivering projects on time, on budget and with minimal disruption. MPDS4 helps our design engineers achieve this objective.”

– Nigel Barnes, Managing Director, CEL International (*now WSP CEL) –

For over 40 years, companies in the pharmaceutical and process industry have found in CEL an invaluable process plant contractor and engineering partner with an impressive range of highly specialised skills. The company’s strengths lie in its flexibility, its comprehensive service offering, and a thorough understanding of the specific challenges its customers face in their market sectors.

CEL’s experts are involved in all stages of process plant projects, from risk analysis and environmental audits in the pre-investment phase; design, procurement, project management and construction in the investment stage; to cost of goods analysis and the removal of bottlenecks in a plant’s operational life. An award-winning company proud of the value and peace of mind it delivers to customers, CEL’s story is one of resilience, determination, adaptation and diversification, which found in MPDS4 an extremely reliable and flexible plant design and automation solution, equal to the diverse and growing demands of its client base.

About CEL

Headquartered in Coventry, the UK’s manufacturing heartland, CEL International has offices throughout the United Kingdom, in Ireland, China, and many other international locations. CEL provides consultancy, design, engineering, procurement, construction/project management and validation services to customers in the pharmaceutical, biotechnology, food & consumer products, industrial & chemical, and energy & environment market sectors.

Specialised consultancy groups include a dedicated in-house environmental resource, and Pluris Engineered Solutions, which focuses on the refurbishment and improvement of existing facilities and the provision of new, fully integrated production lines.

The company, which started out in 1963 doing plant design for paint producing chemical factories, now employs more than 400 people. Having faced down several recessions and harnessed the energy and commitment of its staff through a management buyout in 2000, CEL became part of the WSP Group (one of the world’s fastest-growing design, engineering and management consultancies) in 2007, and remains an autonomous entity, adding unique process engineering expertise to the group.

CEL’s customer list reads like a “Who’s Who” in the pharma and process industry, from famous high street names and food brands to energy and pharmaceutical giants. But Managing Director Nigel Barnes, himself a highly-experienced engineering project manager and former Vice President of Engineering at GlaxoSmithKline, emphasises that the company supports clients of all sizes, from small consultancy projects to full Engineering Procurement Construction Management (EPCM) delivery. “Our services are very flexible, delivered in the way clients need them,” he explains. “Assignments range from a few thousand pounds-worth of advice or smaller plant modification projects to comprehensive capital plant contracts in excess of £50M capital value. We emphasise teamwork, and we’re proud of the passionate group of experts we employ. We ensure close integration with the entire supply chain in order to deliver cost-effective solutions for business improvement, always mindful of best industry practice, safety, quality and sustainability.”

Fast, Reliable Plant Design That Wins Projects

An innovator always keen to deploy the best technology for the job, CEL has been using 3D plant design systems for detailed process plant design and layout for many years. MPDS4 is the company’s system of choice, not only among the users. In a recent open vote among CEL project managers, 10 out of 11 said they preferred to tackle all of their plant design projects with MPDS4, seeing it as the most reliable system, and one that impresses clients and helps to win contracts. The company currently has 14 MPDS jobs live, and has used the product in around 50 contracts.

CEL deploys MPDS4 ADVANCED with supporting modules in all the plant design disciplines, including Steel Design, Process Piping Design with ISOGEN*, Electrical Design, Ducting Design, Hangers & Supports, P&ID, Factory Layout, Mechanical Handling and Engineering Review. The seats also include the MEDUSA4 ADVANCED drafting system with Parametrics and the MEDUSA4 3D modeller.

MPDS4 is our product of choice in the complex process plant design and layout arena. The software supports the flexibility we need as we address diverse engineering challenges in a multitude of market sectors.

Efficient Multi-User Plant Design

Quickly Getting Contractors Up to Speed

On large projects, up to two thirds of the CEL design team may be made up of contractors. Contractors are expected to get up to speed with MPDS4 in about a week, after a day’s in-house training and some hand-holding. “That’s another plus about MPDS,” says Brendan. “It’s easy to learn. I think it’s one of the easiest packages to teach somebody.” Jamie agrees, “I learned on a live job when I first joined. It doesn’t take long to get someone started.”

“Most of the other major plant design products we’re familiar with are so complicated to use that you have to have an external trainer in,” adds Dave Latchem, “What’s worse, some industry standard 2D CAD commands can corrupt the database in those systems, because they use completely different commands. That just doesn’t happen with MPDS.”

Customised for Bespoke Design

Applied Market Knowledge

MPDS4 for Pharmaceutical Process Facility Design

Winning Contracts with MPDS4: On-Site 3D Design Studies

Hydrocarbon Installation Simplification

Dave cites the example of one of the major oil companies, which commissioned CEL to do a design study for a project tender. Jamie Gower, who went to the site, explains, “The job was a simplification project requiring the identification of redundant equipment, so it could be disconnected from the process. All they expected was for us to measure up the site and deliver 2D drawings and a parts list.” Instead, Jamie decided it would be quicker and easier to model the installation in MPDS4, based on existing isos, then automatically produce the required 2D drawings.

He did the work in less time than the estimate for doing it in 2D. “Some people think that you can’t use a model for this kind of scenario, but it was ideal,” says Jamie, “I had the client looking over my shoulder, saying, ‘Can we move this…can we change that..?’ They were very impressed that we delivered a 3D model, and liked MPDS’ flexibility. With that much work already done, we saved an immense amount of time – any company tendering would have had to start the modelling again from scratch. In the end, the company awarded us the simplification contract straightaway.”

Easy to Handle Large, Complex Models

Bio Fuel Plant Project Coordination

CEL recently worked on a new bio fuel plant (a joint project between a major US chemical and UK Oil Company) for which the larger group, WSP, was the building design and construction contractor. The project involved four different contractors.

“First we modelled the building, the slab and the area around it from 2D drawings,” explains Brendan. MPDS4’s FACTORY LAYOUT module allows designers to quickly produce 3D building models based on 2D layouts. “Then we used the model to coordinate all the other disciplines, such as the steelwork and the process, which two other contractors were involved with. We ran clash detection and routed all the services, including the electrical cabling and all the interconnected pipework to tie in the process components (which were slotted into modular frames) inside and outside the building. It was a bit of an unusual way of working, but MPDS is the system that did it.

MPDS4 for Manufacturing Plants

CEL also recently worked on a major glass production plant. “When we bid for the job, we were up against other contractors who were using the same 3D product as the client,” explains Dave Latchem. “But that was a mechanical design package, not a process plant product. Still, we had one day training from the vendor and grilled the instructor about piping, clash detection and isometrics. The product simply wasn’t up to the job, so we went back to the client to say we would be very happy to do the project, but MPDS would be the right tool for the job.”

Integrating External 3D Model Files

Clash Detection

Automatic Piping Isometrics*

Always Someone at the End of the Line

We Never Stop Learning

“The most interesting part of my job is to see what our customers deliver with the help of our software,” says Mark Simpson, “The quality of the services CEL provides to its large and satisfied customer base are the best testament to the value of our solutions. Like CEL, our aim is to provide products and services flexible enough to adapt to the needs of our customer base, and we never stop learning from our clients.”

For more information about CEL visit the the WSP Group Website.

*MPDS4 offers an interface to the ISOGEN™ software, and integrates directly with CAD Schroer’s M4 ISO software (released in 2014). Either software is a prerequisite for creating automated piping isometrics.