Process engineering: Complete overview with examples and tips

Process engineering – what is it?

The processes in process engineering

Process engineering refers to the processes involved in creating a product from raw material. These material change processes are also known as procedures. During the manufacture of a product, multiple processes may be used to transform the raw material.

Process engineering is divided into three main categories:

- Mechanical

- Thermal

- Chemical

Thermal processes are usually more energy-intensive than the mechanical processes, as large amounts of energy or heat are consumed by them. A wide variety of processes, both large and small, take place in a typical process plant and its associated equipment.

Unit operations in process engineering

In order to have a clear understanding of processes, they are divided into so-called unit operations, each of which involves a physical change or chemical transformation. The overall process is only finished when the various unit operations , such as mixing, stirring, sedimentation, filtration, evaporation, etc., have been performed in sequence.

Process engineering in plant design

The realisation of a plant that has been designed using process engineering is called plant design. A plant contains the various equipment, machinery and other devices needed to perform a process. The transformation of material takes place in the equipment. Process engineering concentrates on the processes that occur in the equipment and documents them using computational methods.

Today, increasingly user-friendly software packages are used to solve complex tasks. This applies in particular to the optimisation of processes and documentation. Even faster process engineering design requires modern software that supports and optimises the design process.

Pipework for transportation

The transportation of materials around a plant is often achieved using pipes and conveyors. The chosen means of transportation depends on the material to be moved. Therefore, a distinction is made between the transportation of solids, liquids and gases. The goals of transportation are to move materials safely, gently, quickly and cost-effectively over the shortest possible distance between the units.

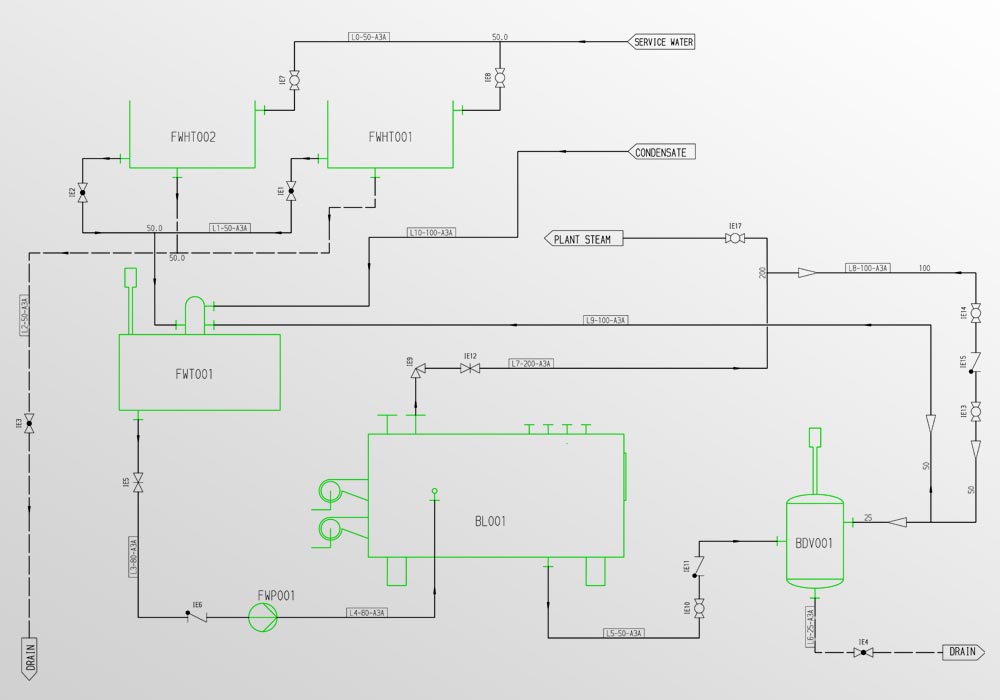

One of the most important means of transportation in process engineering is pipework. Networks of pipes connect individual pieces of equipment to form a system. The pipes supply sources of energy and raw materials. In process engineering, all pipework , equipment and machinery are represented schematically by graphic symbols on a so-called Piping & Instrumentation Diagram (P&ID).

Challenges in process engineering

Realization of a process plant

Lean processes create time to do more

The right software for process engineering design

Modern software supports process engineering design by adding intelligence to Piping & Instrumentation diagrams. This means that the properties of individual components need to be entered only once when placing component symbols. Thereafter, all reports and parts lists can be generated automatically from the diagram of the process engineering design. A modern P&ID software package completely eliminates the need to manually create external documents, thereby saving time and avoiding the risk of human error.