Pipework design: How to minimise your effort

Designing pipework can become a major challenge if the task is approached incorrectly. But with a few simple steps, any company can carry out efficient and effective pipework design. Although this requires a few additional process steps and tools, it greatly simplifies the overall process of pipework design.

What is pipework design?

Pipework design is a process for designing pipework. It also involves the fabrication and installation of the pipework and other fittings to transport liquids or gases. This discipline is present in almost all industries. Pipework design involves the design, fabrication, installation, testing and commissioning of piping systems.

5 steps to better pipework design

With these simple tips, any company can build a comprehensive design process and save time and money with each new project.

Step 1: Define the process

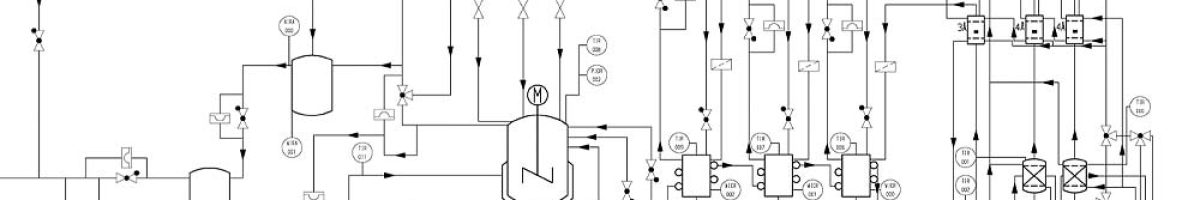

Defining the entire process for a piping system is the first design step. Suitable P&ID software can be used to easily create a piping and intrumentation diagram (P&ID). In just a few minutes, this will clearly show the piping system and how it works on a simple schematic diagram. Already at this stage, parts lists can be generated to give a rough overview of the main components required. At this stage, of course, the P&ID does not provide any information about exactly how much pipe is needed, just the main components that need to be installed and how the system itself is to be constructed.

Step 2: Observe the environment

Comprehensive pipework design should also take into account the terrain and buildings if they have an influence on the course of the pipework. For pipework design, anything that is available in terms of information or data on the surrounding area can be included. This can be terrain data, 2D ground plans, 3D models or laser scans. All of this can be used to represent the terrain and buildings in the project. This data can be imported into comprehensive pipework design software (e.g. M4 PLANT) to aid the design process.

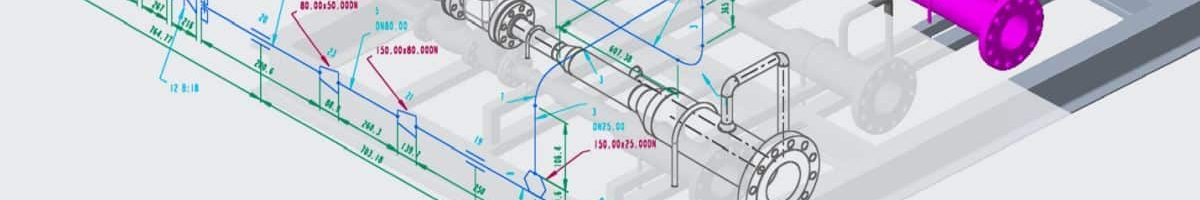

Step 3: Design the pipeline in 3D

With specialised software for pipework design (e.g. M4 PLANT), any company can design extensive pipework with all the associated components in 3D in just a few minutes. Such 3D pipework design software has functionality for many design tasks that would otherwise be difficult and time-consuming. This enables those tasks to be completed in minutes or even completely automatically. For example, autorouting tools or the automatic placement of suitable bends and flanges can be used when designing pipework routes.

The result is always a 3D design of the entire piping system, which also takes the surrounding area into account. Thanks to automated collision checking it can also be determined whether the individual pipes need to be further optimised at certain points. In addition, the 3D design can now be used for visualisation, e.g. to send pictures of the design, the model, or even a video of a tour of the new design, to the customer for review.

Step 4: Parts lists for costing

If steps 1 to 3 have been carried out successfully with suitable software, the rewards for the time invested at the beginning of the project now follow. This is because a lot of project time can now be saved using the 3D pipework design software. This happens, for example, through the automatic generation of detailed parts lists. Here, nothing has to be created or generated manually. Instead, at the push of a button, a complete list of all the components required for the project can be obtained. And of course, exporting the list to Excel or other popular file formats is also possible so that a detailed cost calculation can be made.

Step 5: Documents for fabrication and assembly

When it comes to the documentation of the pipework, different documents are required. For assembly purposes, drawings containing orthoganol views of the pipework from multiple directions are required. These drawings often also contain sectional views to clearly show the course of the pipework through the plant. With these documents, the installation team is optimally prepared. With software such as M4 PLANT, the required drawings can be automatically generated from the 3D design within a few minutes, ready for annotation and dimensioning as required.

Pipeing isometrics are often used for the fabrication of individual pipes. They are also a valuable tool in documentation and quality control. Here too, one now benefits from 3D design because fully-dimensioned Piping isometrics can be automatically created with a click of the mouse from the 3D design. These drawings also include the associated parts list and weld tables, together with the data required for pipe bending machines.

Conclusion

If you perform many manual steps when designing pipework, this can be a clear indication that your processes could be significantly optimised with the help of suitable software.

Simply watch one of our webinars on this topic or contact one of our consultants. You will receive comprehensive advice on all the possibilities that 3D pipework design opens up for you. If you can’t wait to try out the software yourself, you can also download our trial version of M4 PLANT.

FAQ - 3D pipework design

3D pipework design is a process of designing and modelling pipework, valves and equipment in a three-dimensional environment. It is an important process for designing pipework in many industries such as the chemical industry, oil and gas industry, food and beverage industry, pharmaceutical and biotech industry and others.

3D pipework design has the advantage of enabling the creation of an accurate, detailed and realistic model of a piping system. This allows design errors or potential problems to be identified at an early stage. This increases the accuracy of the design, which ultimately saves time and costs. In addition, changes to the model can be made easily and cost-effectively without the need for physical changes to the actual pipeline.

M4 PLANT is a CAD system for pipework design incl. P&ID creation, 3D pipework design, piping isometrics generation as well as building design. There are software modules that can be used for individual disciplines in pipework design or for the entire process plant design. M4 PLANT is a plant design software package that covers the entire pipework design process. If, however, only P&ID software is required, M4 P&ID FX is the right choice. The same applies to the automated creation of piping isometrics with M4 ISO FX.

The 3D pipework design process typically includes the following steps: gathering requirements and specifications, creating a 3D model, reviewing and validating the model, creating manufacturing drawings and bills of materials, and constructing and commissioning the pipework.