What is a piping & instrumentation diagram and how can I quickly create one without errors?

The piping & instrumentation diagram is a highly important document for process plant design. Despite its simplicity, it contains a wide-range of detailed design information. But what exactly is behind a piping & instrumentation diagram?

What is a Piping & Instrumentation Diagram?

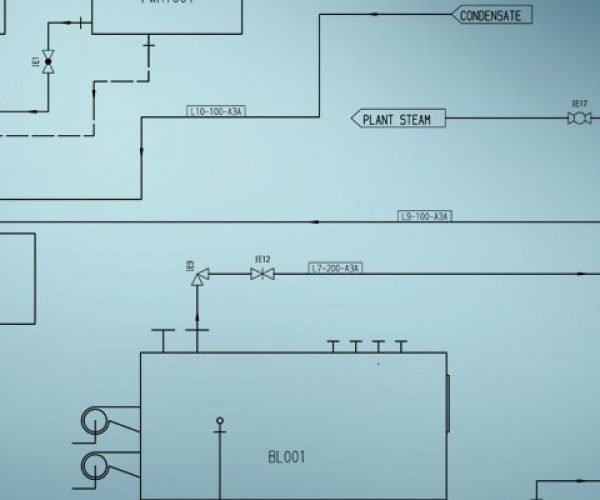

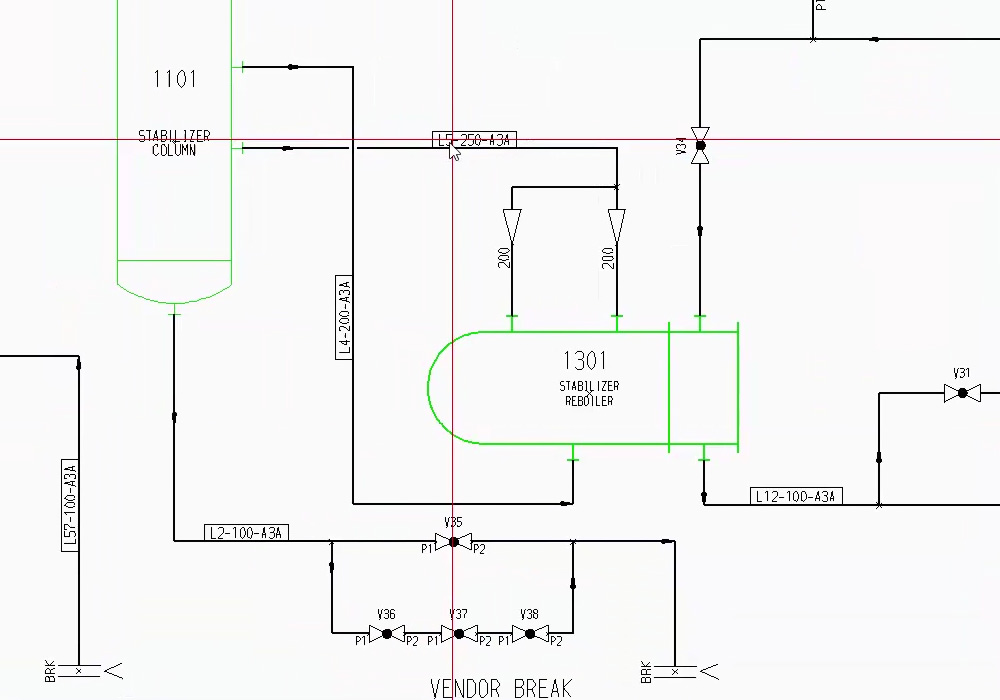

A Piping & instrumentation diagram is the basis for pipework design. Piping & instrumentation diagrams are used to schematically represent a design, and are usually created before any physical equipment design or layout takes place. All of the equipment and instrumentation required for a process is depicted using symbols, and any interconnecting pipework is represented using simple lines. Piping & instrumentation diagrams contain a considerable amount of detailed information about the design such as equipment tags, line labels, bore sizes, quantities and connectivity. But how can so much information be accommodated within such a simple diagram?

Symbols – the aim is to achieve meaningful simplification

Making processes visible

Create a piping & instrumentation diagram, but with which software?

Creating piping & instrumentation diagrams – Without Errors

The piping & instrumentation diagram: the basis for quotations

High level of design detail

A modern system for piping & instrumentation diagrams

Embedding attributes in your Piping & Instrumentation Diagrams

FAQ – Frequently asked questions about piping schematic

Modern programmes for creating piping schematics typically offer standards in the form of symbol libraries as standard. This means that piping schematics can be compiled quickly and are already included in the software package.

P&ID is the abbreviation for “piping and instrumentation diagram” and is a term from process engineering in plant construction. P&ID is often used in conjunction with a P&ID flow diagram, P&ID schematic, P&ID diagram or P&ID piping schematic.