Piping Design: The first step is efficient pipework design

Start » News » News Releases » Piping Design: The first step is efficient pipework design

The advantages of integrated piping design and how to ensure plant design projects are a lasting success

Piping design is one of the most important design disciplines in the field of process engineering. Due to the enormous complexity of modern process plants, specialised software solutions are required for fast, high-quality design implementation.

Designing industrial piping systems for energy and materials supply in process plants

Put simply, a pipe is just a pathway for transporting material. In a process plant, pipes are used to transport different materials such as water, oil and gas. The design of entire pipe systems is an important and essential part of plant design. Pipe systems are not just networks of pipes that transport material from point A to point B. They also provide safety measures for nearby containers, manholes and environmental hazards by transporting hazardous materials only in certain aspects where they will not impact people or animals.

Data breaks are a real challenge for piping design

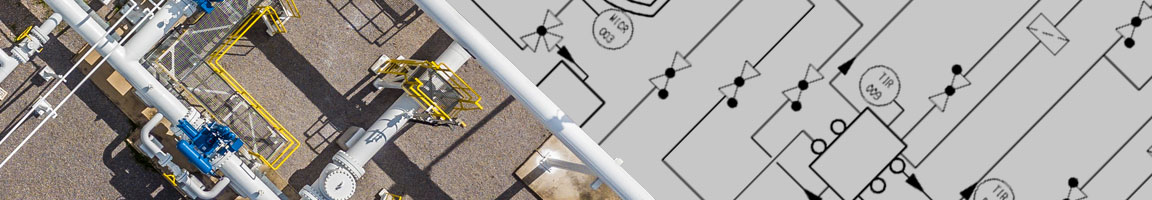

Piping design is often plagued by breaks in data flow between individual project phases. Design concepts often arise as paper sketches and must then be replicated in the form of P&IDs. Parts lists and other reports are often then generated manually. The components and pipework described in the P&IDs then have to be modelled in 3D, which represents another data break. These breaks are a prime opportunity for human error to creep in throughout the design process.

All too often, software is still being used today to create P&IDs as simple graphical illustrations which do not contain detailed information about the individual components and process lines. 3D pipework design is also being performed without the benefit of a standards-based catalogue or consistency checker, even though it is precisely this type of rule-based and specification-driven approach that ensures design quality. Once the 3D pipework design has been finalised, piping isometric drawing are often required for fabrication. Without specialised software to generate the piping isometrics from the 3D pipework model, they have to be drawn manually, which is a laborious, time-consuming process, prone to human error.

A virtual tour through a plant is an impressive way to present the design to the end customer. The improved visualisation with a walkthrough helps to recognise errors at an early stage and thus increase the efficiency of the design process.

Smart design avoids errors in the design and problems at the construction site

For companies that want to set high standards in their industry, the question arises as to what their next steps might be to achieve their goal. How can the automation of design processes be improved, not just marginally, but really taken to a new level? The key to success is to focus on the break points, because no matter how well individual processes may already be digitalised, if there is a break in the transfer of information between processes, the automation stops abruptly and the scope for errors increases. With an integrated software solution for comprehensive plant and pipework design, data breaks can be avoided right from the start.

When designing plants, the challenge is to keep the data and specifications of individual components up to date in all project areas. This concerns areas such as piping design, steel design, cable routing and the creation of piping and instrumentation diagrams (P&IDs). Due to the ever-increasing time and cost pressure in many industries, it is important to manage information efficiently and also to be able to access data quickly. Efficient design also makes it easier to deal with maintenance work, and also more complex tasks such as plant modifications.

"Ready for intelligent plant and piping design?"

The M4 PLANT software offers a wide range of functionality for P&ID creation and 3D plant and piping design. The software also generates fully dimensioned piping isometrics completely automatically from the 3D pipework. The easy to use P&ID tools are an integral part of M4 PLANT. Comprehensive symbol libraries enable the quick and easy creation of P&IDs which contain intelligent attribute information. This valuable data can be reported and used as the basis for subsequent 3D piping design.

The high degree of design automation can considerably shorten design times. Users are provided with extensive catalogues, not only for P&ID creation, but also for 3D pipework and other design disciplines, which further accelerate the design process. With M4 PLANT, CAD Schroer offers an integrated solution for all phases of plant design.

Video tutorial: Efficient Design of Pipelines and Components

This video tutorial shows you how to efficiently design pipelines in M4 PLANT using catalogue components, autorouting and automatic loading. You can also find more video tutorials here:

The piping package for integrated design

The engineering software developer offers a software package specifically for plant & pipework design. It contains all the modules necessary to meet even the most demanding design challenges. The plant design process begins with P&ID creation for which an intelligent P&ID module is provided. Modules are also provided for designing 3D pipework, hangers & supports, steelwork, ducting, cable routing and much more. When the 3D design is complete, 2D drawings can be generated directly from the model. To ensure a seamless integration with manufacturing, fully-dimensioned piping isometric drawings can be automatically produced together with NC pipe-bending instructions, ready for fabrication at the push of a button. In addition, the software can be used to perform interactive 3D walkthroughs and generate videos. The entire plant design can also be exported for viewing in virtual and augmented reality.

Many factors influence efficient piping design

Pipe systems are not just networks of pipes that transport material from one place to another. They also serve as an important safety measure for the environment and surrounding buildings. Without proper design, pipe system construction is time-consuming and inefficient. There are many factors that need to be considered before starting a project, such as the type of material to be used, all nominal sizes up to thick-walled pipes, wall thickness and any conditions such as the length of the pipes and whether there are any obstacles in the way. These tasks can easily be performed with software such as M4 PLANT. This software offers features such as 3D piping design, P&ID creation, the automatic generation of piping isometrics and more, making it easy for engineers to design their piping systems without losing sight of the details.

All modules for piping design in one software package

Piping package: Trial version free of charge for 30 days

The M4 PLANT piping package is available directly from the manufacturer, and gives a rapid return on investment due to its extensive time-saving and quality enhancing functionality for pipework design. A free 30-day downloadable trial of the software is available for new users to try out the software for their own applications. Comprehensive video tutorials and 1-to-1 support are also provided to ensure a rapid start with the software.

Piping design and its importance for the plant engineering industry

The use of a modern plant design system such as M4 PLANT, with its modules for P&ID creation and 3D piping design, ensures consistent piping design. Since this shortens many cost-intensive design steps and completely eliminates manual tasks, the software offers enormous savings potential for piping design. Automated consistency checking and collision detection also avoid unnecessary rework and downtime on the construction site, which can be particularly costly later on in a project.

Efficient design right from the start

The use of a modern plant design system such as M4 PLANT offers enormous savings potential for pipework design. This is because many costly design tasks are streamlined, and manual processes are eliminated. Furthermore, the integrated consistency and interference checkers detect problems that would otherwise cause unnecessary rework and downtime on the construction site, which can be particularly costly later on.

High quality design from the outset is paramount, and by using an intelligent integrated plant design solution, you can ensure your projects will be a lasting success.

FAQ – Frequently asked questions about pipeline construction

Piping design is one of the most important disciplines in the field of plant engineering and deals with the design, production and assembly of pipe systems that are used to transport liquids or gases. Piping design software is used to design pipework. This software is capable of high-quality process design, 3D design and documentation including 2D plan layouts and the automatic generation of piping isometric diagrams, parts lists and pipe bending tables.

One of the most important aspects of pipework construction is design. This should be detailed enough to highlight potential problems or risks during construction and eliminate them in advance. It should also include clear documentation for the whole process. This often includes an initial plan for the layout of the piping system, which includes start and end points and any additional features such as valves or control stations that are required for the function. The detailing of the design is achieved with the help of 3D piping design software, from which conclusions can be drawn about the required space, materials and costs. In the same way, all documents for production, assembly and documentation are generated here.

Piping design in a plant is often characterised by documentation discontinuities between the individual project phases. Ideas or sketches are often created on paper which then have to be digitally captured in the form of P&IDs and then in a 3D design. Parts lists or reports are often generated manually in the process. Continuous piping design eliminates these discontinuities and thus saves an enormous amount of time. For example, sketches can be created directly in digital form and only detailed later. P&IDs then serve directly as the basis for 3D design, from which all further documents and data are generated automatically.

Piping design software should cover three areas: P&ID, 3D piping design and piping isometrics. A software package specially developed for plant & piping design includes all the necessary modules for the designer, starting with P&ID creation and 3D pipework design. Modules for steel design and pipe hangers & supports are also often included, together with other modules that make the job easier and quicker for the piping designer. To ensure seamless integration with manufacturing, fully dimensioned piping isometrics can be automatically created along with NC pipe bending instructions, ready for production at the touch of a button.

The M4 PLANT software offers a wealth of functionality for the creation of P&IDs as well as 3D plant and piping design. The software also generates piping isometrics completely automatically. The easy-to-use P&ID module is an integrated part of the system. Here, symbol libraries enable the quick and easy creation of intelligent P&IDs in which each component can have a variety of additional information. This valuable data can be reported and, due to its intelligent structure, can serve as the basis for subsequent 3D piping design.