Quick-Start Factory Project Service Eases Transition to 3D

Quick implementation and low start-up costs are key for engineers switching from 2D to 3D factory layout or plant design.

Numerous Owner/Operators and engineering project managers still plan their factories in 2D. Contemplating a move to 3D, many worry about the software’s complexity or the implementation burden; but the transition need not be a painful one.

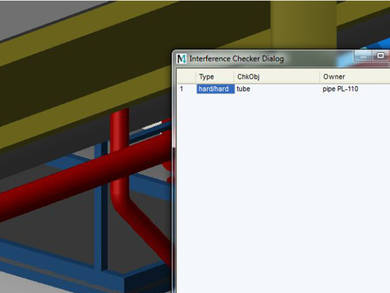

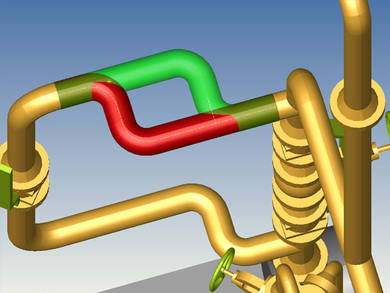

With complex, high tech production lines designed to efficiently use vertical spaces during manufacturing, the spatial element in planning, interference checking, and visualising a factory design becomes ever more vital: A 3D approach makes it easy to communicate plans, and to create high quality designs, avoiding expensive mistakes during construction. For many engineering departments, however, it seems like a big leap.

Size independent design and high performance

“Our researchers speak to myriads of UK manufacturers using standard 2D CAD software for their factory layouts. Most, while aware of the benefits of a 3D approach, have experienced the limits imposed by 3D modelling tools for product (not facility) design, or been shocked by the implementation time and effort associated with some plant design packages, too costly and complex for their needs,” explains Mark Simpson of engineering software experts CAD Schroer. “Recent research in Germany tells a similar story, with most users quoting ease of use and quick implementation as some of the most important criteria when choosing new products . This is exactly where MPDS4 comes in; it not only offers easy implementation with its integrated 2D/3D approach, but also provides all the tools for high performance, large-scale standard-compliant design.”

A Quick Start for 3D Factory Projects

CAD Schroer are experts in easing the transition from 2D to 3D CAD. Its M4 PLANT software is easy to learn even for exclusive 2D users, who can import existing drawings to create the foundation for fast 3D layouts and walk-through visualisations. The QuickStart service further ramps up productivit

The future in 3D

“Our QuickStart package gets a project off the ground in around 15 days,” Mark explains. “We supply everything clients need to tackle a factory refurbishment or adaptation project in a quality controlled 2D to 3D design environment: We install and implement the software, usually in one day, and get users up to speed in three to five days. We can model the existing factory, or a planned new process line in existing spaces, quality checking any 2D drawings or 3D files provided. We then supply the 3D lifecycle model clients need to plan subsequent changes and visualise them in 3D.”

CAD Schroer makes it easy to transition from 2D to 3D, without painful product implementation or training issues. Its QuickStart service makes it easy to tackle the first 3D factory project, quickly paying for itself through significant productivity and quality gains. M4 PLANT factory layout delivers the productivity you need to successfully tackle greenfield or brownfield projects – whether it’s a new build or a refurbishment of an existing factory.