Biogas Plants: Learning from the German Experience

As part of its bid to support renewable energy plant design, CAD Schroer has been looking into the difference between the German and UK biogas markets

Cambridge, UK and Pittsford, NY – 20 November 2014: Over the past few years, the company has exhibited at a number of sustainable energy events, and is offering a 70% software discount on its M4 PLANT 3D plant engineering software to companies involved in the renewable energy market.

UK as a Growth Market

In 2013, Germany already had over 7,700 biogas plants. There, growth is levelling off sharply. In contrast, there were only 97 biogas plants in the UK outside of the water sector , but a predicted 40-50 more to be built within a year, with larger increases in the coming years.

What Can We Learn from Germany?

At a recent conference, CAD Schroer spoke with industry expert Ian Burgess of CHP plant and engine provider SEVA Energie AG. “Firstly, it takes too long for planning applications to go through in Britain,” Ian says. “The process is much quicker in Germany. In the UK …there’s a huge educational process required. People need to see first-hand that (biogas) doesn’t smell; it’s not loud; it’s good for the environment, and creates green energy.”

The UK AD and Biogas Association

Ian also says that more regulations govern UK biogas plants. These keep changing, causing uncertainty in the market. “Costs rise if you need to install scrubbers and noise reduction technology, and pasteurise incoming bio waste,” he explains. “And if the feed-in tariffs don’t stay at an adequate level with a secure guarantee – especially if you need to buy in energy crops – there may not be a pay-back at all.” The UK AD and Biogas Association has been pushing hard for a clear and unified government policy regarding feed-in tariffs and heat incentives. In Germany, government regulations are set down and kept the same. Feed-in tariffs change every four years and are guaranteed for 20 years. This de-risks capital investments.

Concentrate on Food Waste

“Germany really pushed maize crops into the AD systems,” Ian explains. “This brings with it all the disadvantages of monoculture; plus this is land food could be grown on.” He thinks the UK should focus on food waste. “Large supermarkets can meet their own heat and energy needs, and provide enough extra to heat a small town by turning their food waste into biogas, rather than paying £70-80 per ton to send it to landfill.”

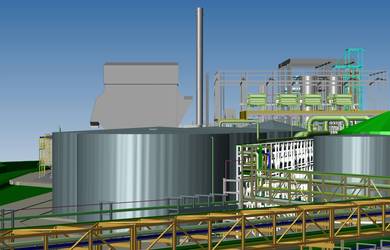

To achieve success in such a large potential market, with its burden of regulatory and financial challenges; two things are vital to vendors. Certainty about the engineering content bringing reliable control of capital costs and high quality 3D presentation of the project brings the highest chance of regulatory approval.

CAD Schroer is totally committed to this renewables market sector offering its M4 PLANT 3D plant design software at 70% discount; making it possible for renewable energy plant providers to plan, present and deliver projects to the highest possible standards.

Related Links

- M4 PLANT Demo Videos

- “Lessons from Germany” (Article Published by Process Engineering based on our interviews)

Footnotes

[1] Fachverband Biogas e.V. : “Entwicklung des jährlichen Zubaus von neuen Biogasanlagen in Deutschland”. (November 2013). Available at: www.biogas.org/edcom/webfvb.nsf/id/DE_Branchenzahlen. Accessed 23 April 2014

[2] According to the UK ADBA. This map is updated periodically to show biogas sites across the UK: http://biogas-info.co.uk/maps/index2.htm

[3] According to a DEFRA report, 123 UK sites have received planning permission, but it is difficult to estimate how many will actually be built: http://www.defra.gov.uk/publications/files/pb13788-ad-2012-progress.pdf

[4] Charlotte Morton, Chief Executive, The Anaerobic Digestion and Biogas Association. Available at: http://www.adbiogas.co.uk/2013/01/25/uk-could-generate-1-5bn-pa-from-household-food-waste/

[5] Statement from Jordan Marshall, Policy Officer, The Anaerobic Digestion and Biogas Association (ADBA)

[6] Ellen MacArthur Foundation: “Towards the circular economy Vol.2: opportunities for the consumer goods sector” (January 2013). Available at: http://www.ellenmacarthurfoundation.org/business/reports/ce2013#

[7] Crowhurst, Richard: “New Choice of Biogas Feedstock Crops” (28 July 2012). Available at: www.fwi.co.uk/articles/28/07/2012/134094/new-choice-of-biogas-feedstock-crops.htm . Accessed 6 February 2013.

[8] Tristram, Stuart: “Sainsbury’s aims for zero waste landfill – but is anaerobic digestion the best way?” (17 November 2011) Available at: www.guardian.co.uk/environment/2011/nov/17/sainsburys-zero-waste-landfill. Accessed 6 February 2013. Detractors argue that the energy generated from food is a tiny fraction of the energy put in, and waste food would be better deployed as livestock feed. Others argue that the issue of food waste itself needs to be addressed.