The virtual factory becomes a reality

The path to a virtual factory

3D factory layout made easy

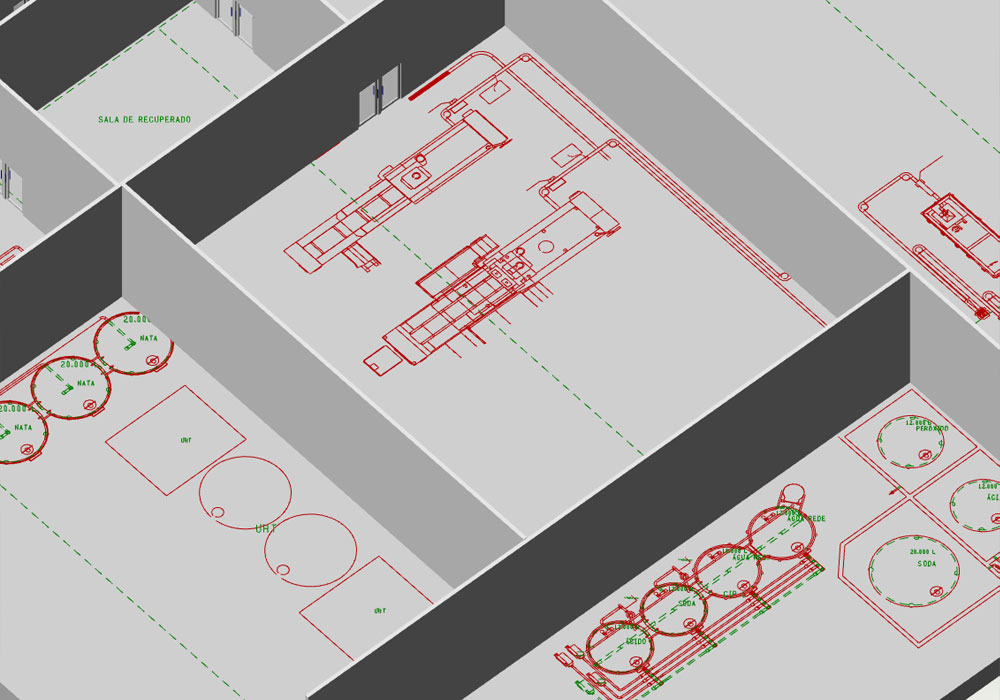

The optimized results for the layout planning are continuously recorded in a 2D system. This does not correspond to the modern factory planning, because quality of the planning decreases strongly with a purely two-dimensional view. However, some CAD software providers also offer the option of transferring 2D planning to 3D planning. All 2D symbols contain a 3D model as a counterpart, so that the 3D planning is automatically carried out with the 2D layout. A clever combination, so that a 3D planning is automatically generated despite the usual 2D working method. The planning can then be further optimized by additional quality controls, such as collision checks.

The added value of a virtual factory

Once the 3D factory layout is finished, it is often further optimized in several project meetings with the team. The feedback of other employees, for example from production or service, is often decisive for the success of the new project. A particularly resource-intensive sub-process is the presentation of the data. Currently, these are presented with the help of a beamer either as videos or in the form of screenshots.

SMEs benefit from modern factory design

Design systems continue to develop

The path from 2D layout to 3D design, to a virtual factory does not have to be complicated. Software providers like CAD Schroer GmbH offer a state of the art solution. With its factory layout software, entire buildings and production lines can be quickly designed, no matter how large or complex they are. The 3D factory model can then be easily exported to the popular FBX format. The FBX file can then be viewed using a VR viewer.

With the i4 VIRTUAL REVIEW VR viewer, which is compatible with Microsoft Mixed Reality, CAD Schroer offers a direct way to achieve and experience a virtual factory. The software developer also supports companies in getting started with VR by providing 3D modelling services to customers whose machinery and buildings are not already available in 3D.

See for yourself M4 PLANT & i4 VIRTUAL REVIEW

Test the 3D factory planning software M4 PLANT yourself now. Download the software and test it. The CAD Schroer team is currently offering free online support for the test phase. Contact us if you would like to test i4 VIRTUAL REVIEW.