Sulzer Pumps Welcomes MEDUSA4 to the Heart of its Design Process

“The move to MEDUSA4 was a great leap forward for Sulzer Pumps. The comprehensive design automation package, modern user interface, and a huge raft of productivity tools provide us with the efficiency and flexibility we need to meet new challenges and develop world class pumping solutions. CAD Schroer’s friendly, professional support has been invaluable. With business booming, and MEDUSA4 now firmly at the centre of our design processes, we can look forward with confidence to the next decades of growth and innovation.”

(Hansjörg Büchler, Chief Information Officer at Sulzer Pumps)

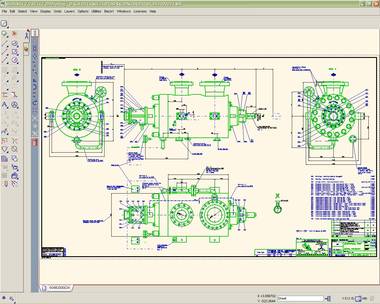

When it’s time to innovate, it’s all hands to the pump at Sulzer’s product research and development centres. The company’s pumping solutions underpin the businesses of clients in industry sectors as diverse as Oil & Gas, Hydrocarbon Processing (HPI), Pulp & Paper, Power Generation, Water & Wastewater, and Food, Metals & Fertilizers. Sulzer Pumps’ products, as the corporate strapline proclaims, are at the heart of its customers’ process. And MEDUSA has been at the heart of the company’s product design and development since 1985, helping to create a hugely profitable business through its extensive design automation capabilities. These have saved so much time and resource that the number of CAD engineers at Sulzer Pumps today, in spite of an exponential growth in orders, is about the same as in the mid-80s. Twenty years on, Sulzer Pumps was one of the first customers to take the leap forward to MEDUSA4, the Fourth Generation release, and CAD Schroer’s flagship product line.

About Sulzer Pumps

Sulzer Pumps Ltd Winterthur – At the Heart of it All

At the Forefront of Research and Development

Its strong R&D culture has made Sulzer Pumps a leader in high-pressure applications and special materials. The Swiss office houses Sulzer Pumps’ technical research and development team: 30 engineers, most of them MEDUSA users, who support the subsidiary companies – its primary customers – in many areas of product design.

“Our main focus is on hydraulics,” explains Heike Tischler, design engineer in Switzerland, who project managed the MEDUSA4 roll-out across Sulzer Pumps worldwide. “We spend a lot of time looking at this area to improve pump performance, and continually develop our products. We also focus on mechanical development. If one of our subsidiaries sells a very specialised pump (such as an oil rig fire fighting pump, which has huge pressure requirements) then we do all of the development work here for them. In addition, we are always researching the market to discover new niches.”

Hansjörg Büchler, Chief Information Officer, is in charge of “IT all”. He coordinates IT activities across all the Sulzer Pumps companies, including ERP and infrastructure issues, and had overall responsibility for the MEDUSA4 migration. “We act as special consultants to our subsidiaries, tackling challenges in custom pump projects. Our engineers also act as an overflow resource where workloads demand.”

From Special to Mainstream

MEDUSA Then and Now

Combining a Good Heart with a Fair Face

“With MEDUSA4, we signalled to loyal and new customers that we are ready for the next millennium,” says Gilbert Koch. “Other than completely refreshing the user interface and greatly improving speed and performance, access to power tools, and many ways to make central administration and QA a breeze, technical innovations included click-and-drag design editing tools which do not rely on full constraints (SMART Edit), lots of quick and intuitive drag and drop functionality, and easy group structuring any time in the design process. Really, there’s too much to mention here.” The MEDUSA4 product suite covers 2D drafting and Parametrics, powerful “sheet-based” 3D modelling, 2D to 3D Plant Design and Factory Layout, Electrical Design, and a huge number of add-on options, from standard parts libraries to SAP® or Pro/ENGINEER® interfaces.

Getting Ready

Sulzer Pumps was one of the first customers to recognise the overwhelming benefits of the latest release, and proceed with its worldwide migration. HQ in Winterthur develops and implements the company’s global IT strategy, and managed the MEDUSA4 upgrade and international roll-out.

“We didn’t take up every new revision or version of MEDUSA that was released,” says Heike Tischler, “But I first went to an M4 workshop, then CAD Schroer came to present the new version, and we were all very impressed. There was a lot of extra functionality, the user interface was drastically improved, and it was much easier to use. The DWG format support was also comprehensive and in line with the latest AutoCAD® version, which is important when we deal with customer data.”

Mr Büchler saw the upgrade as a great opportunity to do some stocktaking and housekeeping. “We did an analysis focusing on how we work today, and got rid of all the unnecessary clutter, exploring how to best take advantage of all the benefits of the new system, for example by porting our existing Bacis1 code to Bacis2, meaning all the old text-entry macros were replaced by user-friendly dialogs, which our designers really appreciate.”

CAD Schroer had been commissioned to do the initial requirements analysis, “and they provided a framework for the migration, setting out how we should best go about it, and how we should prepare for it. That was very well organised,” says Ms Tischler.

CSG’s consultants also rewrote or ported existing customisations, some of which completely automate the design creation process, and developed specific tools requested by various locations, which were then rolled into the central package.

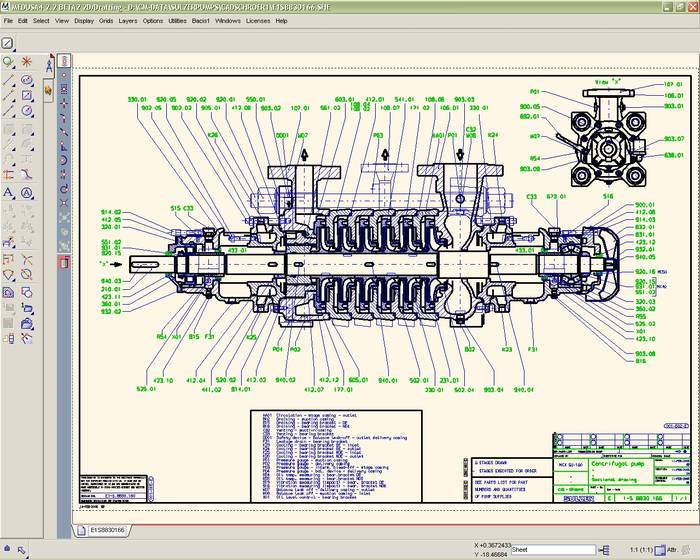

Achim Maihöfer, CAD Schroer’s chief consultant on the project, developed a tool enabling designers to select a whole series of half symmetrical dimensions (displayed from the centre line) and automatically shorten them as much as possible in order to create clearer, more legible drawings. Alternatively, users can move them manually.

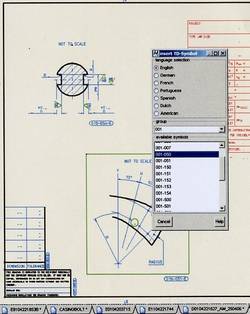

“CAD Schroer also improved our existing TD functionality,” explains Heike Tischler, “This is a very useful tool we were able to develop as an extension to MEDUSA, allowing us to easily produce designs in seven languages.” TDs are symbols, which are made up of 2 parts; one graphical, the other text. Each symbol ID identifies the text as belonging to a specific language, so that users can translate drawings by exchanging the symbols.

Building Bridges

Each company in the Sulzer Pumps family uses MEDUSA for slightly different requirements. “Here in Switzerland we focus on R & D,” explains Heike Tischler, “while the German design office, for example, does its work based on customer orders.” Nevertheless the aim of the project, as Hansjörg Büchler points out, was to standardise as much as possible, and specialise only where absolutely necessary.

“This is where our expertise is highly relevant,” says Achim Maihöfer. “As external consultants speaking to various stakeholders in Sulzer Pumps, we are able to see where departmental/geographical requirements differ, and how to best consolidate those requirements technically. Often, we are able to build bridges between different ways of working, and simplify processes via specific customisations.” Different locations may, for example, adhere to different release mechanisms, use different numbering schemes for drawings, or need different sheet header information. Providing solutions that suit most locations, without too much specialised development, means less administrative and maintenance overheads. “The key is to understand company needs on a strategic as well as operational level,” adds Gilbert Koch.

Rolling it Out

When Swiss headquarters rolled out MEDUSA4 across its Sulzer Pumps locations, the upgrade affected 27 floating licenses in Germany, 21 in the UK, 13 in Brazil, 7 in France, 7 in Canada, 6 in Switzerland, 4 in South Africa, and 3 in India. The licenses are used by around 120 engineers. The roll-out across the subsidiaries went very smoothly, with both Ms Tischler and Mr Büchler lauding the close working relationship with CSG’s Swiss office.

“We built the whole installation pack here in Switzerland, then made the software available to all countries, so that the roll-out took place more or less simultaneously, really without any hitches,” says Mr Büchler.

“We were very satisfied with the migration process, and the support we received from CAD Schroer, especially Mr Maihöfer, really was great. And to this day his colleague Heinz Wegmann is helping us out with user advice, which we very much appreciate,” adds Heike Tischler.

The Proof of the Pudding

But the proof of the pudding, as they say, is in the eating, and a major new software release means change, and none of us like change, especially designers who have been working with a system comfortably for nearly 20 years; know its ins and outs, and have their special way of working.

“Everyone really likes the new user interface, which makes so many things simpler than before,” says Ms Tischler. “Of course it takes some time for users to adapt to some of the new, and particularly changed, functionality.”

She cites the case of the new group structure concept, which she loves, because it enables here to simply start drawing, and then add structure later. “And it’s so much easier now, the Explorer-style ability to click and drag.” Still, some colleagues, who disciplined themselves to group their components during design creation, may mourn the old clump structure for a while.

“Newer users, or those with an AutoCAD background, like myself, don’t have any issues with concepts that allow designers just to go wild and start drawing, then add structure later – and of course there are so many additional things one simply couldn’t do in AutoCAD,” adds Ms Tischler.

“That’s a very normal, if not always easy, situation when you have a major software upgrade,” says Gilbert Koch. “Those people that use MEDUSA every day find it easy to adapt, and we run workshops where we follow up our training with some personal hand-holding – often it’s a simple thing – showing someone how to do something quicker – that makes all the difference.”

We visited one of Sulzer Pumps’ largest subsidiaries to find out how the migration worked for them.

A Case in Point: Sulzer Pumps Germany

Pumps by Design

“We focus on pre-engineered pumps, created from a catalogue of variants, which are customised to suit individual requirements, mostly for hydrocarbon processing and power generation applications,” explains Mr Pfeiffer. Unlike some other German firms, Sulzer Pumps’ business is booming and staff numbers growing: “80% of our products head for export markets.”

Its product list is impressive and expanding, as the company fosters organic growth, as well as acquiring key players in niche markets, such as the 2006 purchase of Crown Pumps, Texas, which specialises in submersible vertical turbine pumps. Sulzer now offers over 46 different series of pumps, ranging from single stage to barrel, to ring section, to axial split and vertical pumps.

Its business is based on orders received from intermediary installation design firms, which typically provide the complete package (e.g. complete fire fighting installations for oil rigs) to the end customer.

Net sales in Germany have been very strong, with 2006 proving to be a bumper year. Pumps only make up 50% of sales; the other half comes from maintenance and consultancy services. In 2005 the German firm manufactured 721 pumps; many of which run into the tens and hundreds of thousands of Euros in cost. Sulzer Pumps’ overall sales were up over 26.4% in 2005 compared with 2004, with a 55.4% increase in operating income.

Projects of all Sizes

“Ours is not a mass market product,” explains Mr Reichert, “We very much work on a project basis. Our customers define the extent of the order – which is usually an aggregate including the pump, the motor (these we buy in based on customer specifications), seals, couplings, coolers etc. Sometimes all we get from them is a drawing title block with a logo. Sometimes we get an installation framework. In terms of P&IDs, there are often prescribed numbering systems, and the seal or motor suppliers provide us with some basic data, which we process with our MEDUSA drawings. End customers want their documentation in various CAD formats. This was one of the reasons for upgrading to MEDUSA4 – its excellent data exchange capabilities with AutoCAD and other systems.”

Mr Hasenfus adds, “There is really never a case when a standard pump doesn’t have to be customised in some way or another, even if it’s just an installation diagram, or a new motor added to the aggregate.”

Projects can take from 5-6 months for small pumps, to several years for large projects.

The ESCRAVOS Project

The largest project currently under way is called ESCRAVOS. It involves oil fields in Nigeria, where Chevron is building a new refinery to process the gases created during the oil extraction process. In the past this gas was often burned, but in accordance with the Kyoto Protocol, and supported by higher oil prices, Chevron will now be using state of the art technology to turn the gas into liquid form and transport it to a large refinery, where it is turned into petrol. Sulzer Pumps is the main pump supplier for the refinery, as well as for the network of pipelines which will carry the gas from the oil fields to the plant.

“It is a truly global project,” says Mr Pfeiffer, “We have nine full time staff members working on ESCRAVOS over a 2-year period, and we’ve hired one new MEDUSA design engineer specifically for this project. We’re talking about 90 pumps, and a 20 million Euro value. The majority of the pumps will be delivered to Nigeria straight from our factories in India, Mexico, the U.S., South Africa and the UK, but Germany is handling all the project management.” There are four large contractors involved, as are some of the world’s largest motor, seal and coupling suppliers.

MEDUSA at the Core

Engineers at Sulzer Pumps in Germany have been working with MEDUSA since 1985 to design new pre-engineered pumps, modify existing designs, and create complex custom pump packages for special applications.

When orders are received, MEDUSA experts like Mr Hasenfus and Mr Luft straightaway start with the design process, first creating a general arrangement drawing. Then existing pump designs are customised both internally and externally, taking into consideration materials, pressure requirements, the liquids they will be pumping etc. They then add pipes, seals, and other components, producing separate component drawings. Finally, the designers produce the layout and the plan view of the pump. Customers often receive basic drawings as PDFs or in paper format, along with schematic drawings like P&IDs with pump placement in order to plan for electrics, piping etc.

Managing Change

When MEDUSA4 arrived in Germany, the changeover was relatively pain-free, as the leg work had already been done by CAD Schroer and the Swiss head office.

“There were quite a few details we had to consider when integrating a standard CAD parts solution, for example,” says Achim Maihöfer, who worked closely with teams in Germany, “and we worked to ensure customers could easily benefit from the new Styles concept in MEDUSA4. We did the mappings to achieve consistent results, and also introduced special line styles required by the South African team. This iterative process ensured that drawings from all locations would convert seamlessly.”

“As a result, I had no issues with design conversion whatsoever,” says Winfried Reichert. “I wanted to get our whole stock updated in one go, so I did a batch conversion. It took four to six hours on two machines to convert 80,000 drawings to MEDUSA4 – a piece of cake.”

Georg Hasenfus adds, “The migration to M4 was pretty straightforward – unlike the change from tablet to screen menus! The way of working has changed fairly fundamentally, but – and we saw this during the training session – experienced MEDUSA users quickly got the hang of it.”

Worldwide user training was coordinated to take place almost simultaneously, with CAD Schroer providing training direct in Germany, Switzerland, and France, and via close partners in the rest of the world. MEDUSA4 Administrator courses were completed shortly beforehand, ensuring that each location had a primary contact for users and CSG Technical Support alike.

“One of the things I can’t stress enough is the need for good administrator and upgrade courses for end users; especially in a case like this, where there was such a leap forward from the version of MEDUSA Sulzer Pumps had previously deployed and the new generation version,” says Gilbert Koch. “When users learn how to best exploit new tools and functionality, productivity levels soar.”

A Faint Heart Never Won Fair Lady

As IT Managers know only too well, product upgrades which involve new versions with a breadth of new functionality, new possibilities and a brand new user interface, require a well thought-out strategy, especially when dealing with multiple companies and locations. Implementation teams take into consideration all aspects of the corporate infrastructure and processes, technical as well as human. The key to success lies in effective change management and communication: detailed planning and evaluation, coupled with a close, efficient partnership between the customer’s implementation team and their systems supplier.

Mr Büchler’s recommendation: “I would strongly advise anyone following in our footsteps to get CAD Schroer’s consultants involved with a requirements analysis from the very beginning. Make sure that everyone in the team is singing off the same hymn sheet, and has the latest information. Then execute the project with a solid project plan with firm milestones.”

At Sulzer Pumps, a challenging international roll-out worked smoothly because of good planning, and excellent communication between the customer and CAD Schroer.

“The move to MEDUSA4 was a great leap forward for Sulzer Pumps,” concludes Mr Büchler, ”The comprehensive design automation package, modern user interface, and a huge raft of productivity tools provides us with the efficiency and flexibility we need to meet new challenges and develop world class pumping solutions. CAD Schroer’s friendly, professional support has been invaluable. With business booming, and MEDUSA4 now firmly at the centre of our design processes, we can look forward with confidence to the next decades of growth and innovation.”