Reifenhäuser - 25 Years of Project Success with MEDUSA4

Plasticizing Machinery and Plant Design with MEDUSA4

“MEDUSA4 has been and remains the best 2D system for us. Its parametric functionality, comprehensive interfaces, extremely compact data format, and a transparent data structure are all big advantages. MEDUSA4 offers drafting freedom and flexibility with a myriad of design options; at the same time, it is easy to create a clear and mandatory structure for users to work within, drastically reducing errors and ensuring standards compliance.”

– Joachim Bremer, Technical Services Manager at Reifenhäuser –

Reifenhäuser Group, a global leader providing innovative technology, machinery and plants to the plastics processing industry, recently marked the 25th anniversary of its adoption of CAD Schroer’s MEDUSA4 CAD software for fast and effective project planning, design and delivery.

Reifenhäuser Group Worldwide

Over 25 Years of Successful Teamwork

Innovation has always been key to Reifenhäuser’s R&D projects. Technical Services Manager Joachim Bremer remembers his 1985 remit to acquire a future-proof CAD system. The company chose the MEDUSA software, which even then distinguished itself through its advanced parametric capabilities, its coherent data structure and compact data format. What started as a five-seater pilot project soon developed into a long-term technology strategy and partnership.

MEDUSA’s flexibility made it easy for Reifenhäuser to grow its software portfolio to optimise corporate processes. When the 3D product development software Pro/ENGINEER® was introduced in 1999, MEDUSA remained highly competitive as one of the few drafting systems to offer a comprehensive Pro/ENGINEER interface. A high quality DXF/DWG interface also ensured seamless data exchange with customers and suppliers.

A Long-Term Partnership

From Detailed Design to Layout Drawings

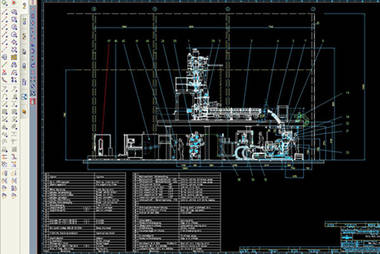

All assembly and layout drawings are created exclusively with MEDUSA4, which is used to amalgamate project data from all other systems during this part of the design process. Reifenhäuser’s sales engineers also use MEDUSA4 as a presentation tool on their laptops during customer visits, where client feedback can immediately be integrated into the design, and project data amended accordingly.

The year 2010 is a special marker in the longstanding, successful partnership between CAD Schroer and Reifenhäuser. After 25 years of project success, MEDUSA4 remains pivotal to the relationship – a fact that was celebrated by both companies on September 1, 2010 at Reifenhäuser’s headquarters in Troisdorf, Germany.

For more information about Reifenhäuser, please visit www.reifenhauser-group.com