KFC ENGINEERING

The challenge

Über KFC Engineering

Italian-based KFC Engineering specialises in cooling systems for the food industry. The company supports its customers from the initial consultation to the finished design and the realisation of the cooling systems.

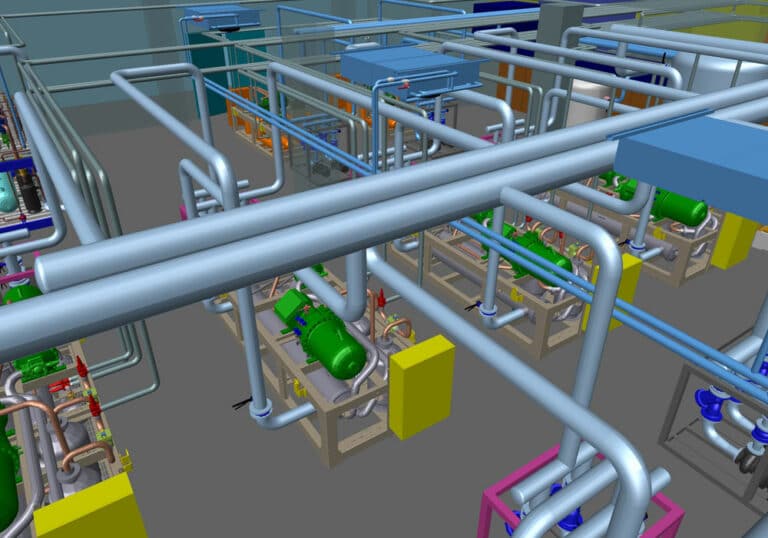

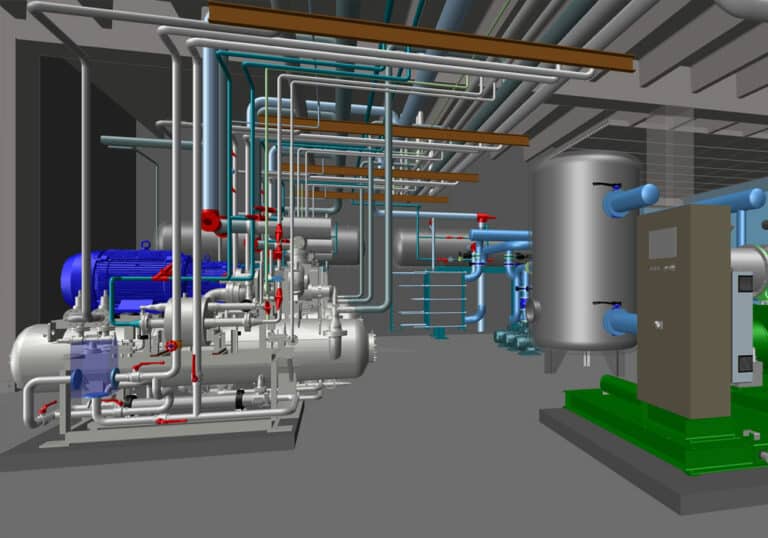

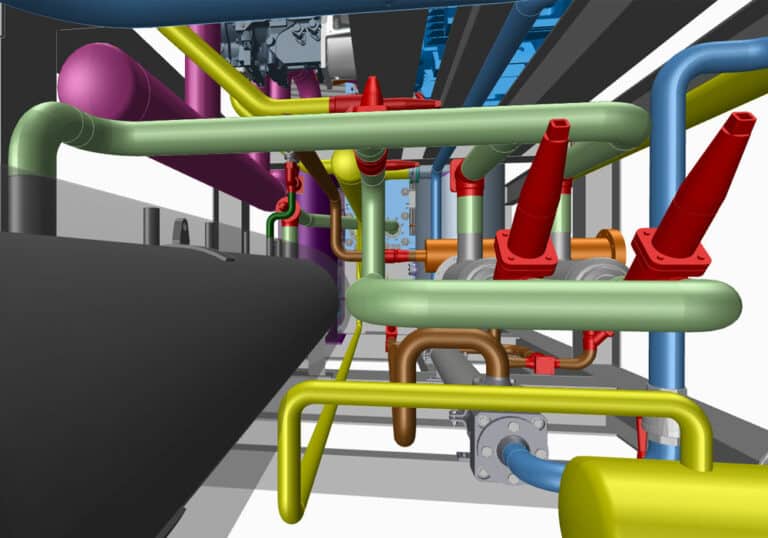

KFC Engineering was founded by several experts from the refrigeration industry. Shortly after its inception, the company decided to design its cooling systems with professional tools, thus offering its customers the highest level of quality combined with rapid design. This is because the past experience of KFC shows that quality suffers with purely 2D design, and also that a standard 3D CAD system simply cannot handle the size of the models required. Nor do they provide the tools necessary to create an integrated piping design.

The solution

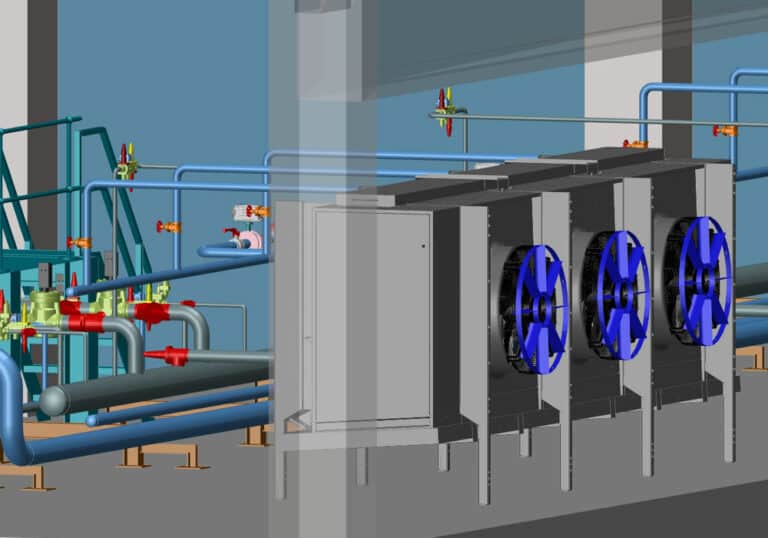

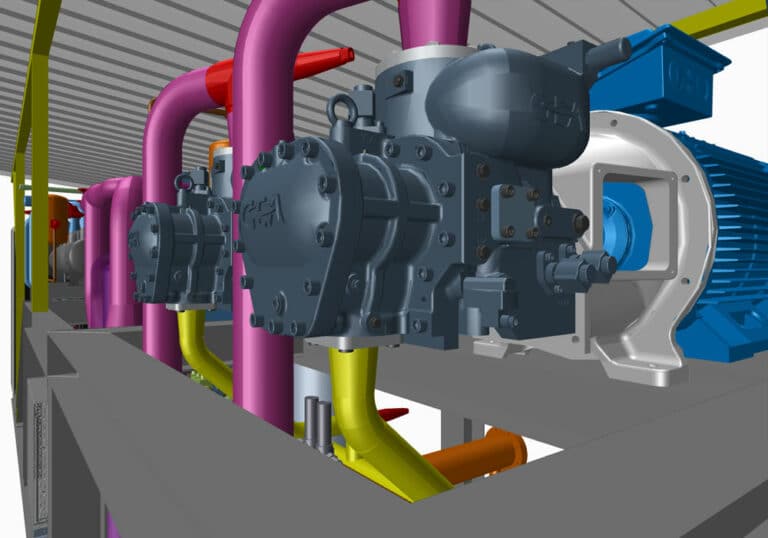

After researching, KFC Engineering had three different software packages demonstrated to them. An expert from CAD Schroer also gave a detailed on-site presentation of M4 PLANT. All key system functionality was demonstrated, such as P&ID design, pipework design, steelwork design and building layout. Particularly important was the freedom to work efficiently even with large models from different suppliers. Exporting the models also had to be easy. The various quality assurance mechanisms, such as collision detection and parts listing, were also discussed. Drawing generation and automated piping isometric generation also played a role.

“The decision in favour of M4 PLANT was particularly based on the high performance that the software displayed in the design of even very large plants. Equally decisive was the range of functionality geared towards plant engineering,” says Fabrizio Paoloni from KFC Engineering.

The implementation

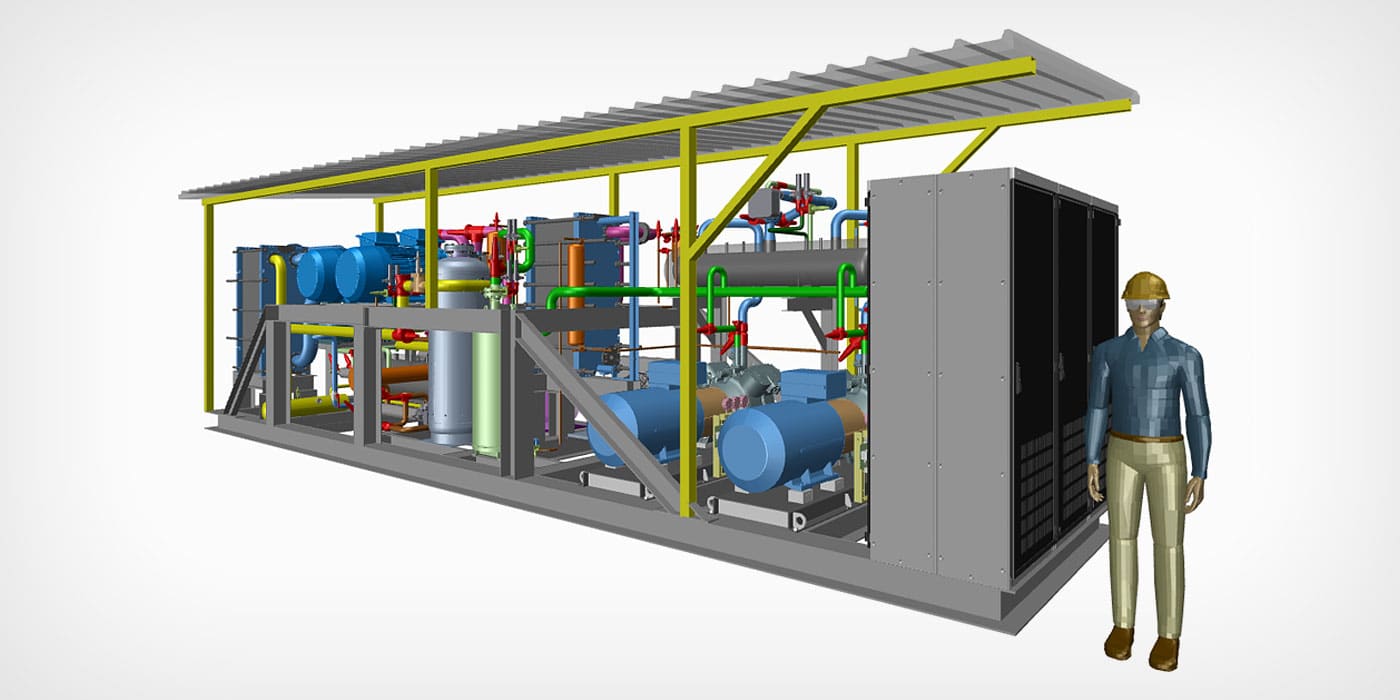

During the first steps with the software and the introduction of M4 PLANT, KFC Engineering was supported by CAD Schroer experts so that they could learn the software directly on their projects. Thus, a customer project was designed during a project-accompanying workshop. Training on the job brings enormous advantages compared to regular software training.

The result

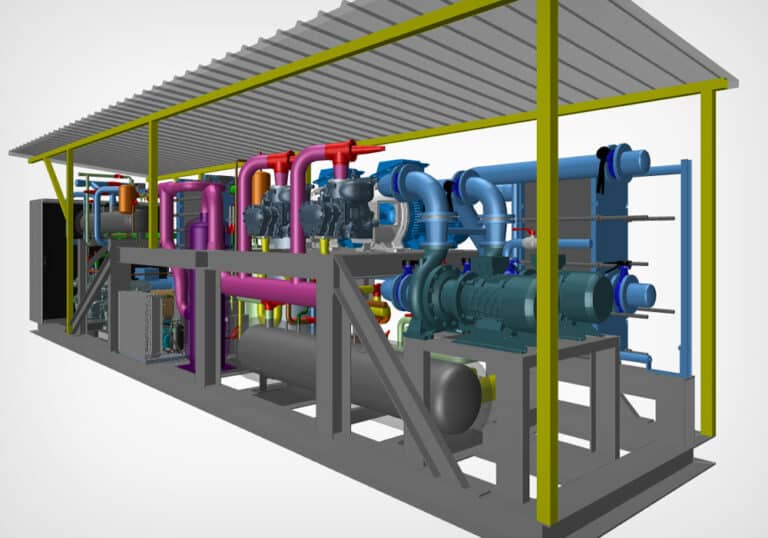

Since its introduction, KFC Engineering has been working continuously with M4 PLANT and uses it to design small to very large refrigeration plants. Thanks to the regular software updates, the company is now also able to use BIM data in its design processes. M4 PLANT can now import even more extensive models and visualise projects even better. A viewer also ensures smooth communication with customers.