Factory Modelling Prevents Painful Problems

Spatial design capabilities prove critical for factory operators who regularly change layouts and machinery

Cambridge, UK and Pittsford, NY: Modifying a factory based on 2D legacy drawings can be risky. Mistakes caused by omissions or a lack of 3D clash detection can incur huge costs during construction. CAD Schroer’s new factory modelling service prevents such painful problems.

Factories have a life that spans decades, so it’s no surprise that many Owner/Operators have a wealth of incomplete paper layouts or digital 2D drawings which only document part of the current set-up. As facilities gear up for flexible manufacturing, regularly changing in order to quickly introduce new product lines or the latest equipment, an accurate lifecycle model of a factory becomes vital.

Factory Modelling Service Overview

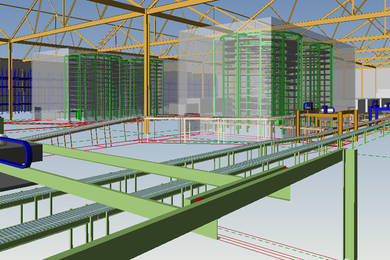

Engineering software provider CAD Schroer has recognised this trend, and now offers a factory modelling service as part of its solutions. “Many factories have project-driven engineering departments handling layout design in-house,” explains Bill Wilkins, Technical Sales Manager at CAD Schroer UK. “Where complex production processes run on multiple factory levels, changes require detailed knowledge of what’s already there, how it’s positioned (hard space) and what space is required to move, run and maintain equipment (soft space). When there is spatial complexity, 2D drawings are an invitation to get things wrong or omit important information, which translates into unplanned down-time and expensive re-work if new lines don’t fit into existing spaces.”

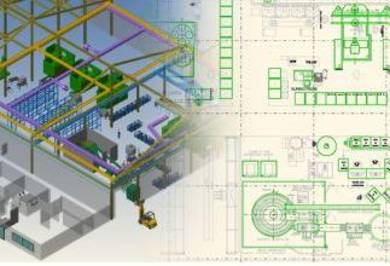

2D to 3D

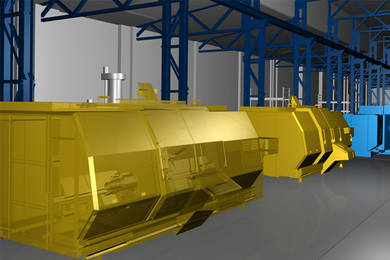

The service speeds up projects, easing the transition between 2D drawings and a 3D factory lifecycle model. Clients can focus on planning changes, rather than on the CAD data needed to proceed. Bill adds, “The model created is based on existing data (scanned drawings, 2D CAD data, 3D machinery models). We report and resolve inconsistencies we find along the way. Where no up-to-date drawings exist, laser scanning can provide the data needed for a model.” CAD Schroer delivers the factory model and the software needed to plan changes. Users edit project data interactively in the 2D layout or 3D spatial design environment. Hard and soft clash detection and consistency checking ensure accuracy.

Easy-to-use 3D walk-through tools visualise plans for internal and external stakeholders

CAD Schroer’s factory modelling service and its catalog-driven large-scale modelling system M4 PLANT take the pain out of factory projects, delivering all the data Operators need to gain control over their capital assets, plan and deliver changes, without expensive surprises on-site.