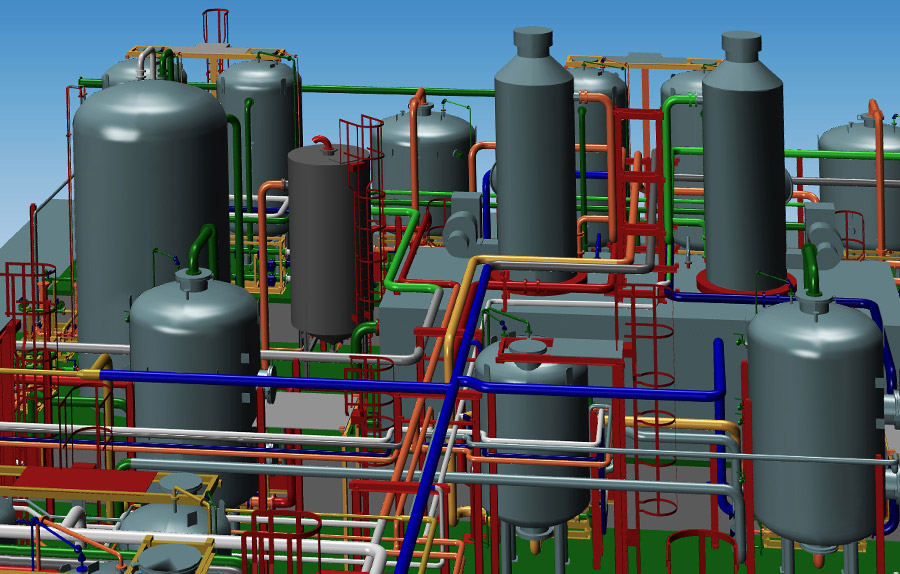

Integrated piping design: Efficient from P&ID to 3D and isometrics

Pipeline design has evolved considerably in recent years. Whereas P&IDs, 3D models, and isometrics were once created separately, modern companies now rely on integrated piping design.

Traditionally, piping design was carried out in several separate steps. P&IDs were created manually, often without direct interfaces to 3D design. All relevant data was then recorded in a separate table. Pipelines were then drawn in 2D or created using simple CAD programs. The piping isometrics, which were required for the production and documentation of the pipework, were created manually in another software program. These three separate steps were error-prone, as no common database existed.

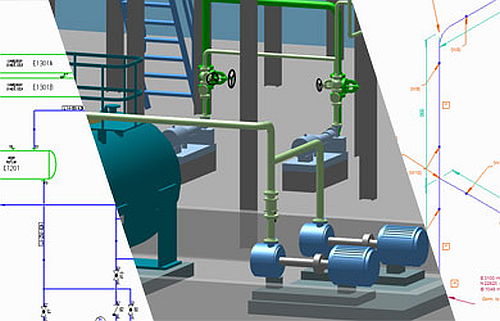

From the idea to 3D system design: P&ID as a foundation

Continuous data flow: from 3D design to automatic piping isometrics

The interaction of P&ID, 3D piping construction and piping isometrics

The creation of parts lists in integrated design

A central component of piping design is the parts list, which lists all the parts, materials and components required for a system.

In traditional design processes, these lists were often created manually and maintained in separate tables, which was error-prone and time-consuming. Modern software solutions enable the automatic generation of parts lists directly from the 3D model or even from the P&ID data. Pipes, valves and other components are precisely recorded and brought together in a structured and consistent list. This automation not only saves time but also increases accuracy.

One major advantage is the dynamic updating of parts lists: changes to the design, such as moving a valve or adjusting a pipe diameter, are automatically reflected in the parts list. This means that purchasing, production, and assembly always work with up-to-date data, the material flow is optimised, and errors in material logistics can be minimised. The integration of the parts list improves the efficiency of the entire piping design and contributes to the project’s cost-efficiency.

Advantages of integrated piping design

1. Reduced design times

2. Avoidance of design errors

3. Automated creation of production documents

Modern software solutions allow the automatic generation of:

- Parts lists

- Piping isometrics

- Welding tables

- Bending tables

This automation saves time and ensures greater accuracy.

4. Collision check in 3D design

5. Automatic quality inspection

Automated data flows and increased efficiency

Engineers and companies benefit in several ways thanks to the seamless link between P&ID, 3D piping design and isometrics. On the one hand, the shared database ensures automatic quality assurance: if, for example, a component is changed in the P&ID design, this information flows directly into the 3D model and ultimately appears correctly in the piping isometrics. In addition, it eliminates many manual work steps, such as when creating parts lists or production documents, which significantly shortens project lead times and reduces costs. Last but not least, the integrated approach creates a high level of design reliability, as everyone involved has access to the same level of information and can, therefore, work together smoothly. This efficient interaction positively affects all phases of the system life cycle – from the initial concept idea to subsequent maintenance and expansion.

Challenges of collaboration between different

Several teams are involved in piping design – from process engineers and designers to production and maintenance teams. One of the biggest challenges is that these teams often work in different software environments with different specialisms. Misunderstandings, inconsistencies, and time-consuming coordination can occur without a centralised data source. Changes to one part of the design often have to be manually updated elsewhere, which increases the risk of errors. An integrated design solution facilitates collaboration by providing a shared, constantly updated database and improving communication between teams.

An integrated software solution

Integrated software that combines the creation of P&IDs, 3D piping design, and the automatic generation of piping isometrics can realise all these work steps. One example is M4 PLANT, which is tailored precisely to these processes. Companies can optimise their design processes even further by using an integrated solution because all relevant data and design steps take place under one roof. This leads to higher design quality, saves time, and ultimately reduces project costs.