High-Efficiency Industrial Cooling Technology

“Thanks to M4 PLANT we have gained access to new design possibilities and can now design our compressors ever more precisely. In addition, our customers benefit from a more accurate overview of the installation layout and can quickly provide us with feedback. With the help of M4 PLANT, design errors and mistakes have become an absolute rarity for us, and our design times have also greatly reduced. This led to significant time and cost savings for the company.”

Mario Corcione, designer at CO-REF Srl.

CO-REF – High-quality compressors for the cooling and deep-freeze industry

When shopping for frozen food, consumers expect top quality and freshness. Until food is prepared and served, whether it be vegetable, fish or meat, it needs to remain fresh and completely frozen. In order to achieve this, it is vital that fresh produce is frozen as quickly as possible during the production process. CO-REF Srl, based in Italy, are a major supplier of compressor systems which utilise Howden screw compressors.

The company was established in 1988 and, since then, has continuously developed its offering through the use of cutting edge technology, towards the goal of highest efficiency. Today, CO-REF Srl is a leader the field of compressor production for the cooling and deep-freeze industry.

High demands in the deep-freeze industry

The challenges of tailor-made compressors

M4 PLANT offers a comprehensive solution for compressor design

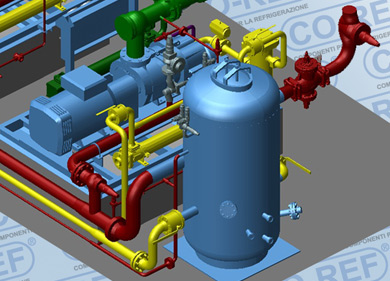

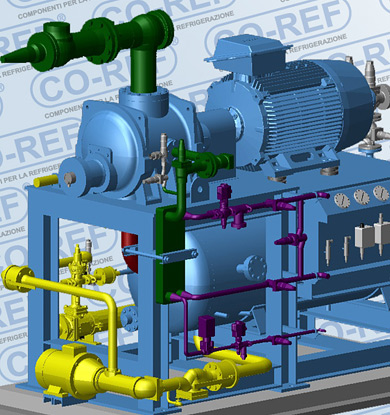

By using the M4 PLANT plant design & factory layout software to design compressor systems, CO-REF gains a competitive advantage with the ability to produce high-quality, large-scale designs. ‘CO-REF is an innovative company with very high standards. M4 PLANT is capable of meeting all of CO-REF’s requirements and helps the company to acquire new projects and customers every day,’ explains Marco Destefani, CO-REF customer advisor at CAD Schroer.

The M4 PLANT system offers extensive 2D and 3D interfaces, which enable CO-REF to effortlessly exchange data with customers and suppliers. Moreover, comprehensive 3D modelling capabilities facilitate the design of CO-REF’s own parts, and specialised tools for pipework design, underpinned by standards-based piping component catalogues, enable CO-REF to quickly design and route complex pipework. Once a design is complete, construction drawings and detailed parts lists can be quickly generated directly from the model.

Bigger projects with higher complexity

“Thanks to M4 PLANT we have gained access to new design possibilities and can now design our compressors ever more precisely. In addition, our customers benefit from a more accurate overview of the installation layout and can quickly provide us with feedback,” says Mario Corcione, designer at CO-REF. “With the help of M4 PLANT, design errors and mistakes have become an absolute rarity for us, and our design times have also greatly reduced. This led to significant time and cost savings for the company.”

M4 PLANT enabled CO-REF to raise the design quality of it compressor units. Costly mistakes during assembly were therefore minimised. In addition, the company can now also undertake larger projects, with a much higher level of complexity, and with significantly more components than before. By designing in 3D, CO-REF is able to communicate and review the design far more effectively with the customer, to the extent that the customer can inspect the design at the very first meeting and provide immediate feedback.

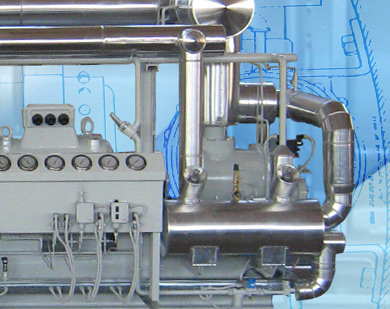

3D visualisation and much more

During the redesign of its website, CO-REF decided to present its product portfolio using an impressive overview video. A selection of individual compressor components and the overall product range were to be shown in detail. Using M4 PLANT’s interfacing capabilities, CO-REF was able to export detailed 3D models ready for use within a video rendering program. This facilitated the production of a comprehensive video-based product presentation. ‘We are very proud of our innovative products. Through the use of M4 PLANT, we finally have the ideal way to showcase our products,’ explains Mario Corcione of CO-REF.