Do you still draw your piping isometrics?

The advantages of automated piping isometric generation

Piping isometrics are the standard

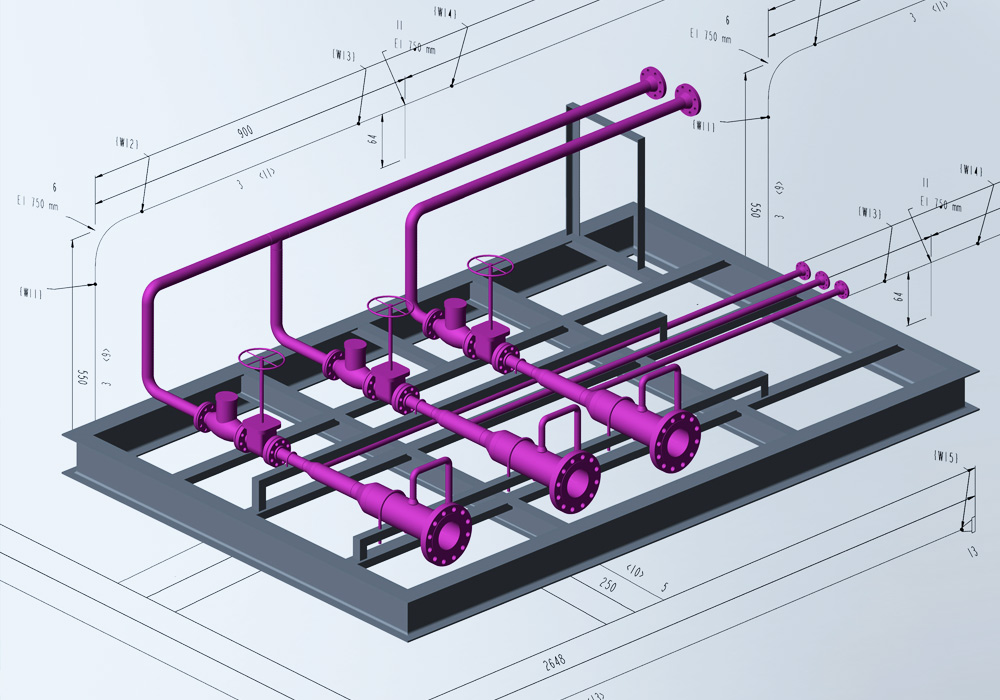

3D solutions for pipework design

Currently available 3D solutions for pipework design, such as M4 PLANT or Creo® Piping, offer an easy way to quickly design pipework for a machine or plant. At the same time, these solutions also offer the possibility to automatically generate parts lists, 2D layout drawings, and piping isometrics at the push of a button. This capability saves companies huge amounts of time and eliminates human error, which in turn means that the software quickly pays for itself, often over the course of the very first project.

Fast, automated generation of piping isometrics

An intelligent approach is to use 3D pipework data from M4 PLANT or Creo Piping to automatically create unscaled piping isometrics complete with parts lists, cut-length lists and pipe-bending tables, ready for manufacture. This can be achieved using M4 ISO, a software package that automatically generates piping isometrics using 3D pipework design data. The production-ready piping isometrics are delivered in seconds, styled to company standards. This is an immense advantage when compared to manual isometric drafting which is much more difficult, time-consuming and error-prone, and therefore far more expensive.

Directly integrates with pipework design

M4 ISO integrates directly into your Creo, M4 PLANT and Windchill environment to provide invaluable automation. At the push of a button, piping isometric drawings are automatically generated for selected pipelines in just a few seconds. In addition, M4 ISO also generates associated documents such as parts lists and pipe-bending tables. The documents are delivered ready for entry into Windchill to ensure further integration with company processes.

Production-Ready Documentation

A change is highly advisable

If you already design your pipework with Creo Piping or M4 PLANT, you can use M4 ISO to benefit from the advantages of an automated solution. If you do not have a 3D solution for pipework design, then a change is highly advisable. This is because systems such as Creo, M4 PLANT and M4 ISO enable you to achieve greatly increased productivity, high design quality, and accurate production-ready documentation.