PALFINGER & MEDUSA4 – Lifetime Excellence

PALFINGER Invests in CAD Schroer’s MEDUSA4 2D/3D MCAD Suite for Advanced Design Automation

The world renowned specialist crane manufacturer counts on CAD Schroer’s flexible design software for the automated production of technical specifications and assembly instructions

The Austrian company recently invested in the fourth generation of CAD Schroers product suite. PALFINGER’s special highly customised engineering design environment provides the company with the greatest degree of automation and flexibility.

Quality & Performance without Compromise

Keeping Up-to-Date

Long-lasting Quality Demands Easy Adaptations

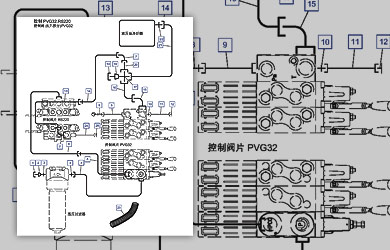

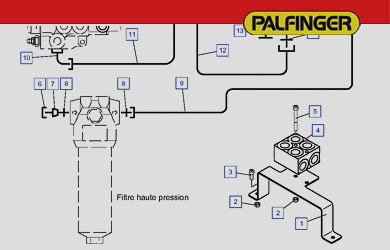

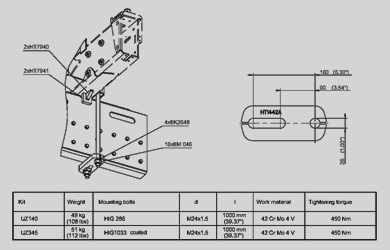

PALFINGER’s products have a lifecycle that spans many decades. Dealers, workshops and service centres can rely on clear assembly and maintenance instructions, as well as the long-term availability of spare parts. “That means that our design and documentation departments are looking after around 95,000 MEDUSA drawings, all of which may be subject to modifications. These include detailed component designs for manufacture; assembly drawings, layouts and special sheet metal designs,” says Johannes Bauer, Team Leader and Project Manager at PALFINGER.

PALFINGER will be deploying MEDUSA4 on Windows (like its predecessor on Solaris) in those areas which demand speed, user friendly design (including easy 3D for traditional 2D users) and customisability. The software is used for manufacturing drawings and design modifications best done in 2D (In 1999, PALFINGER introduced PTC’s Pro/ENGINEER/Creo 3D MCAD software, which integrates with MEDUSA, for new product development); for 2D layouts; and for creating technical specifications.

Automatically Created Product and Spare Parts Catalogs

Sheet Metal Design with MEDUSA4 SMD

PTC Creo® und Windchill® PDMLink™ Integration

Intelligent Use and Management of Manufacturing Drawings

Lean and Automated

“The things we were able to achieve with MEDUSA on Solaris will become even easier and more streamlined with MEDUSA4 on Windows. It means we can retire some of our own developments, and integrate more tightly with third party systems, leading to leaner processes and simpler automation,“ says Mr Binggl. MEDUSA4 supports PALFINGER in the targeted deployment of flexible, integrated engineering and data management solutions, offering the highest degree of productivity in every area of product design, and doing justice to the company’s brand values of efficiency, reliability and innovation. Gilbert Koch, Managing Director at CAD Schroer AG in Switzerland, which looks after the PALFINGER account, concludes, “We’re proud to see our efforts in developing leading edge engineering solutions pay off for customers as forward-thinking as PALFINGER, which uses our software to help automate complex design and documentation processes.“

For more information about PALFINGER, please visit www.palfinger.com