CERALEP and MEDUSA4: Supporting Engineering Tradition

Porcelain Insulator Design with MEDUSA4

“We really appreciate the dedication, responsiveness and professionalism of the CAD Schroer France team, particularly the technical expertise provided by Mr Crabbe. Thanks to our partnership with CAD Schroer, we have been able to develop design functionality that supports our unique processes. This has significantly reduced design times, and thus the time it takes to respond to our customers. Together with CAD Schroer France we continue to optimise and automate our design processes and systems to achieve the ultimate in performance and ease of use. We know we can count on CAD Schroer to deliver and develop solutions that meet our expectations and help fulfil our customers’ product requirements.”

– Emmanuel Mottin, Design Office Manager at CERALEP SN

About CERALEP SN

Tools that change with business needs

A varied and unique portfolio

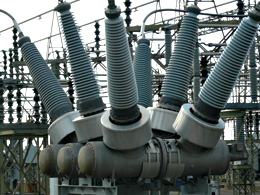

From Desktop to Substation

Automatically Generated Electrical Insulator Design

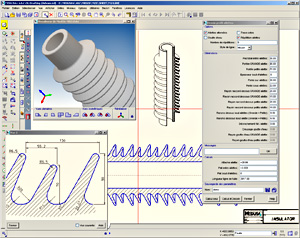

In the early days of MEDUSA Classic, then MEDUSA NG, CERALEP’s designers used a batch tool to automatically draw the profile of two or three insulator disks based on parameters provided in their MDB database. Designers then manually extended the profile to create a complete insulator drawing.

With the advent of the MEDUSA4 (the Fourth Generation) – developed by CAD Schroer after acquiring the software – things became much more automated: CAD Schroer France developed a new interactive tool for CERALEP. The tool provides a user input dialog for choosing drawing options and entering the required dimensions, such as shed span width, the radii of the connectors underneath each shed, the chamfers beneath and above the sheds, the type of profile etc. The software performs a calculation, reports any errors (e.g. a clash in data input) and then automatically creates fully dimensioned electrical disc insulator drawings.

If designers change any of the parameters, the software automatically recalculates and redraws the design. Users can then save their definition for re-use in other projects.

The result is an integrated solution which has significantly cut design times and offers a quick, efficient and consistent way for CERALEP’s design team to respond to client requirements.

Say it in 3D

With the upgrade to the MEDUSA4 ADVANCED package, CERALEP now also uses basic 3D to quickly create complete drawings with isometric views and 3D models of insulators, which allow its customers to see exactly what the finished product will look like.

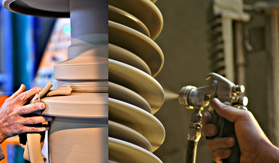

Expert Manufacturing

CAD Schroer France and CERALEP’s engineers continue to work together to further automate design processes and look forward to implementing new ideas well into the future.

For more information about CERALEP, please visit www.ceralep.com.